Sow Group Housing Conversion Answers Animal Welfare Concerns

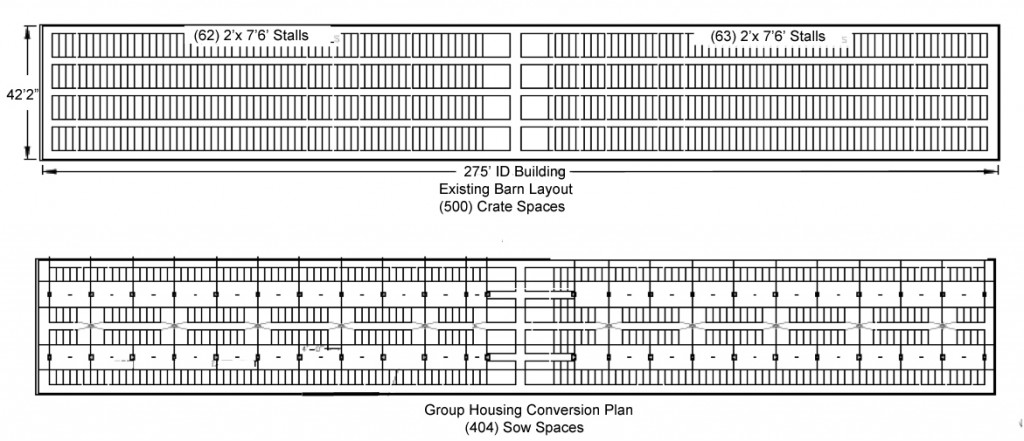

US - Murphy-Brown’s North Division completed one of the largest stall to group housing conversions in the industry, writes Hog Slat's Scott Bauck.All the company farms have been converted to group housing over the last four years, including 58,000 sows in total. Keith Allen, Murphy-Brown's General Manager North Division, discussed the conversion.

How did you decide on the type of group system?

“Long before we announced our conversion plans, we toured several types of housing systems abroad; ESF (electronic sow feeding), free-access stalls and pens with feeding stations or stanchions. We felt stanchions would require the least amount of cost and would be easiest to manage. The results, four years post conversion, support that decision.”

Can you explain further?

Can you explain further?

“Our production records validate improvements for any metric you can compare, pigs born, pigs weaned, etc. The company farm production records rank better than most contract growers with stall gestation. Sow mortally is neutral when compared to traditional stall operations in the system. Fighting is less than we expected. Although we anticipated higher feed consumption in gestation, it also has remained neutral.”

Do you manage any other types of group housing systems to compare stanchions to?

“We have a large 10,500-sow unit with ESF feeding stations. The repair and maintenance of the feeding stations require a full time employee on this operation. There is extra labor involved with the management of the animals. Every day the computer system prints a list of animals that didn’t record entry into the ESF from the previous day. An employee must locate those animals and identify why. Is she sick? Did she lose her tag? Is the feeding station in need of repair? We just don’t have the extra labor costs or the maintenance in our stanchion type barns.

Free access stalls don’t have the same issues, but are more expensive to construct and present an increased opportunity of equipment failure with the gate latching mechanism. There is also a chance an employee inadvertently or purposely could lock the animals in the stalls, and then we really don’t have loose pen housing anymore.”

How did the transition go on the farms?

“The transition was seamless; our employees now prefer stanchions to the stall system we used before.”

What are the basic design requirements you used?

“We designed the pens to hold six sows with 24 square feet per animal; there is one feeding stanchion per sow. The stanchions are 24” wide, and the dividers are 18” long. The length of the divider is important; this divider should be long enough to extend past the shoulders. By extending past her shoulder, she feels more comfortable and secure when eating.

The facility design provides breeding stalls to house sows for 35 to 42 days post-insemination. After preg-checking, sows are grouped by size and moved to the pens.”

“An additional 3% to 5% of stalls have been added in the group housed gestation barns to provide critical care space for any animals that may require extra care or must be removed from the pens.”

Have you made changes to the design over time?

Have you made changes to the design over time?

“Yes, our original layouts allowed for 7% extra stalls in the group housed gestation barns. We have since cut that back to only 3% to 5%.”

“We have also realized it is unnecessary to have an alleyway between rows in group housed gestation. We simply mount the stanchions and sow feed drops head to head. One of the things you lose with group housing is the ability to regulate individual feed intake. You manage by pens, so there isn’t a lot of adjustment to the drops.”

“We also have added “access doors” to the pen dividers to make it easier to walk from pen to pen. These consist of two posts set far enough apart that a person can squeeze through with a swinging solid divider on top to prevent the animals from attempting to go over the opening. We no longer have to climb pen dividers to check sows.”

How have the changes been viewed by Smithfield’s customers?

“I have personally toured many representatives from large food companies through our remodeled facilities. These companies made public commitments to securing pork from “stall-free” producers by a named date. They are listening to the consumer and committed to their long term sustainability programs. In every case, the food company representatives have remarked how well cared for the animals seemed to be and remarked how clean the facilities were. We think we have answered their concerns with this type of group housing.”

For more information on group sow housing, click here.