Agitator Adjusts Position to Current Filling Level

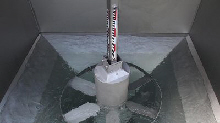

GERMANY - Big Dutchman has been awarded a Silver Medal by the organisers of the upcoming EuroTier show for its liquid feeding innovation.With the current state of the technology, solid and liquid feed components are only mixed ideally at a specific filling level in the mixing tanks of liquid feeding systems for pigs. The reason: the agitator blades are fixed to the drive shaft.

At EuroTier 2014, Big Dutchman can now present a level-controlled agitator, which automatically adjusts its position to the filling level in the mixing tank. This allows the pig manager for the first time ever to mix different feed quantities ideally in the same tank – with the mixture constantly remaining homogeneous. The quality of the feed is improved and operating costs are reduced.

Prior to the show, Big Dutchman innovation was awarded a silver medal by an international expert commission of the “DLG” (German Agricultural Society).

A float guarantees that the agitator is always in the ideal position for mixing, depending on the filling level. Spinning agitator blades not even immersed in feed are a thing of the past, just like blades which are so low in the liquid that a homogeneous mixing of the components is not possible.

The result is a recipe whose ingredients are mixed perfectly at nearly every filling level. Furthermore, the tanks remain cleaner because very little liquid hits the walls. The improved hygiene in the tanks reduces efforts required for cleaning.

Farmers who have to feed groups of different sizes or pigs of different ages will particularly benefit from the new, level-controlled agitator. It can be retrofitted into existing Big Dutchman liquid feeding systems.