Achieving high-quality pork: Superior genetics & proper animal-carcass handling

In this issue of the Pig Improver, we explore facts, both well-known and maybe not as well-known, about achieving consistent high quality pork.Let’s begin with the known facts.

All segments of the pork industry seek consistent high quality pork that incorporates characteristics such as:

- Great taste, tenderness and juiciness

- High ultimate pH with good water-holding capacity and processing characteristics

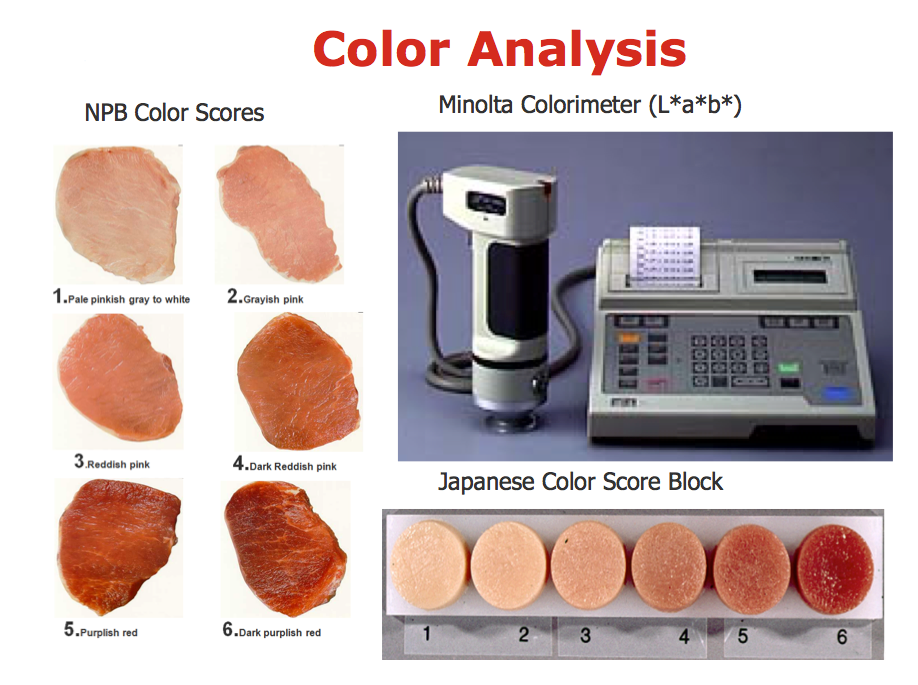

- Reddish-pink colour with optimal marbling

- Produced and safely, with animal welfare in mind

Various segments of the pork market may prioritise different meat quality attributes. For example, the market for cooked, ready-to-eat meat products may primarily focus on technological meat quality attributes such as water-holding capacity. On the other hand, the fresh pork market may focus more on sensory traits related to meat quality such as lean colour and ultimately, eating experience (tenderness, juiciness, taste and flavour).

Now, here’s what is not commonly known:

Five facts that may not be well known about pork quality

1. The value of pH is critical

The importance of pH in achieving high-quality pork may not be widely known. In fact, ultimate pH of the pork (measured 18-24 hours post-mortem) is the pivotal trait (and best predictor) of high pork quality, due to its high correlation with sensory traits like tenderness and juiciness.

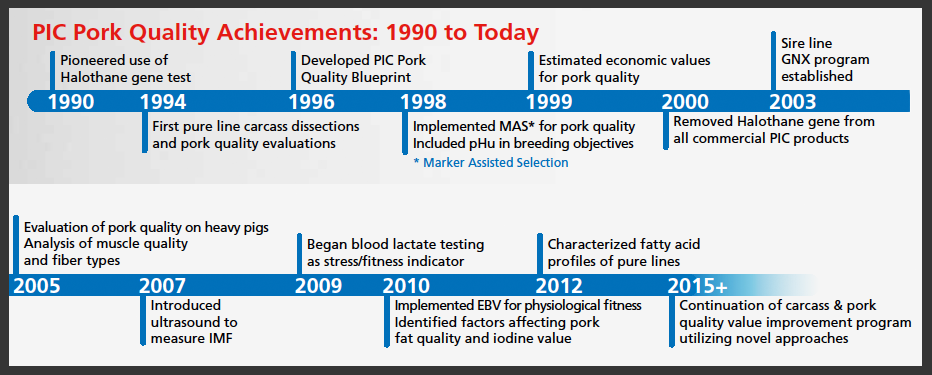

PIC has been selecting for ultimate pH in its breeding programs since 1998. PIC closely monitors the correlation of this trait with meat color, eating experience characteristics (taste, juiciness, tenderness), and processing characteristics such as water holding capacity.

2. Ultimate pH (and therefore pork quality) is affected by two main factors:

GENETICS and ENVIRONMENT, which includes:

- Nutrition

- Feed withdrawal

- Loading (welfare/stress management)

- Transportation conditions (welfare/stress management)

- Unloading (welfare/stress management)

- Lairage and movement in packing plant (rest time and conditions)

- Handling during stunning

- Handling during stun to chill

- Carcass chilling conditions

3. Environmental factors on farm, in transport, and during handling at the slaughter plant generally cause more variation in pork quality than genetics do. In fact, handling of animals before and during slaughter, and carcasses after slaughter account for approximately 60 to 70 percent of the variation in pork quality traits (De Vries et al., 1994).

4. It is also not well known that beyond focusing on genetic improvement to achieve high pork quality, PIC also focuses on providing the critical technical support to help the industry control the environmental components of pork quality. These environmental components will be explained in our next Pig Improver. “In providing this technical support,” explains Brandon Fields, PIC Applied Meat Scientist, “PIC is equipping the industry with the understanding of how to produce high-quality pork in a way that no other genetics company does.”

5. PIC is constantly driving innovation to help the industry ensure high pork quality. Significant milestones since the 1990s are highlighted below:

Some of these milestones relate to PIC’s genetic improvement program and some relate to achieving a better scientific and biological understanding of environmental factors involved in the production of high-quality pork.

This Pig Improver article is the first in a series on pork quality that we will release over the coming months. If you have any questions or want to go in more detail, please reach out to your PIC account manager.