Pig finishing: Danish farmer hosts Open Day with social distancing

Bidding farewell to sow management, Lars Jensen from Aars in Northern Denmark has started finishing pigs on his farmstead “Kællingtandgaard” (“Lotus farm”). For this operational restructuring, the farmer built a new barn, which houses 6,000 pigs today. The milling system that produces cereals for the pigs’ feed is also new. The family-owned company called Stensager Svin I/S recently inaugurated the new pig house and extended an invitation for an Open Day on this occasion. It was accepted by quite a crowd: around 500 visitors used the opportunity to take a closer look at the new building and the Big Dutchman pig equipment and mill – maintaining a safe distance due to the Coronavirus, of course. Social distancing is also guaranteed when watching the video linked below, in which the happy farmer presents his latest project.

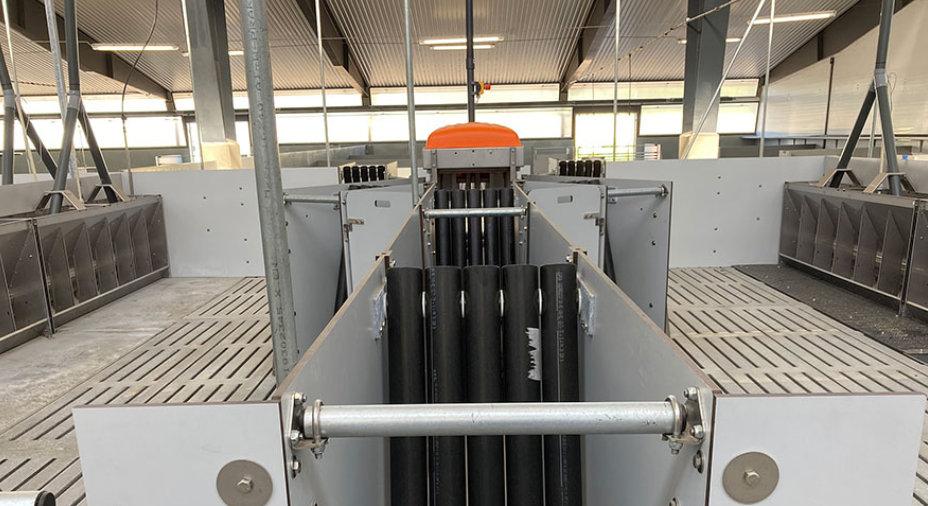

The central part of the new pig house is the TriSortpro sorting scale, which automatically weighs the pigs in the group and sorts them according to their weight.

Construction of the barn took six months, and three of them called for special circumstances due to the Coronavirus. Despite these adversities, the system was completed as planned – while observing all precautions. “This was only possible because we have flexible partners who were all absolutely motivated,” says Lars Jensen, looking back at the effort. On site, Big Dutchman Scandinavia was responsible for the projectThe animal area is divided into six sections, each of which consists of two areas: “500 girls on one side and 500 boys on the other side,” explains pig manager Jensen with a wink.

TriSort sorting scale for pig finishing

Jensen’s pigs live in large groups and therefore have much room to move. The TriSort sorting scale defines the group size for this management type: 250 to 400 pigs per group are ideal. The scale determines the weight as well as the number of pigs that are ready for slaughter, ensuring that they precisely match the slaughtering criteria. Pigs that weigh more or less than the required slaughtering weight are a thing of the past, with a positive effect on the farm profits.

Thanks to this constant monitoring, Jensen knows the daily weight gains of his pigs at all times, which also offers information about their health, since weight loss often indicates diseases. Pigs that require special attention can easily be selected thanks to automatic colour marking, and feed distribution can be adjusted accordingly.

A new product in the Big Dutchman portfolio is the innovative colour sensor: it automatically detects pigs that are marked blue so they can be sorted into the correct area of the barn. “This functionality is a great help. I no longer need to separate the pigs from the group manually, which saves a lot of time,” says Lars Jensen about this optional, labour-saving accessory.

The TriSort stations are controlled by the 510 base controller. It can control up to ten TriSort stations, has an intuitive user interface and shows a full overview of all connected TriSort stations.

Additional TriSort features:

- switching between the station’s modes (training, sorting, selecting) is very easy;

- settings can be adjusted for single stations or simultaneously for multiple stations;

- the controller can be installed in the pen or outside of the central aisle;

- weight predictions are possible for multiple stations at the same time, i.e. pigs from several pens can easily be grouped for slaughter.

Pig house management with BigFarmNet

“It was important to me that the pigs can be monitored individually, so the environment for every single pig is perfect. At the same time, I manage a very large farm,” says Lars Jensen about the conditions that had to be reconciled.

The solution: Big Dutchman Scandinavia integrated the entire production process on Kællingtandgaard into the BigFarmNet pig house management system, i.e. all applications, from feeding to TriSort, are part of one software and one database. Inputs can be made at any computer or via smartphone.

With BigFarmNet, the farmer saves time and can ensure an impressive degree of animal welfare, monitoring and traceability.

Big Dutchman also supplied:

- DryWet feeders – for weaners and finishing pigs;

- DryExactpro dry feeding system – from the silo discharge to the feeder;

- conveying technology – from the lorry to the silo.

You would like to view the barn from the inside? No problem! A happy Lars Jensen is looking forward to showing you his project.