You need a better chain disk corner

Avoid jams and time consuming fixesThe corners are undoubtedly the weakest link on any chain disk system. Over time any moisture entering the corner mixes with the feed to create a jam or causes the corner wheel bearing to seize. The chain continues to slip around the locked wheels, which adds stress to the entire system and can eventually damage the nylon disks, drive sprockets, motor, and gearbox.

Solid plastic corner housings make it tough to detect when a corner is not functioning. In most cases, several corners will lock up, causing a current overload that shuts down the system before the jammed corners are detected. Since the housings are solid, the only way to find the locked-up corners is to disassemble each one. This search can take up a lot of time, with some systems having up to 24 corners.

Several manufacturers have developed corners with clear housings to detect locked-up corners more easily. While it is easier to find a jammed corner, there are still 16 nuts and bolts to disassemble before removing the feed. Attempts to build a corner with locking cams instead of bolted housing have not proven successful. Also, clear polycarbonate housings are not as robust as those constructed with solid plastic material.

|

| Transparent door flips open to remove any feed buildups |

Hog Slat's E-Z Clean corner offers a novel solution by combining a solid housing with a clear viewing panel to simplify the detection of problems. Much of the design work focused on preventing moisture from entering the unit. The reinforced polymer housing features gasketed tongue and groove molding to create a moisture barrier and is securely fastened together with stainless steel bolts. The domed top section sheds water while rubber backed washer seals the axle.

|

| Flexible gasket fits into the molded groove to seal the door when shut |

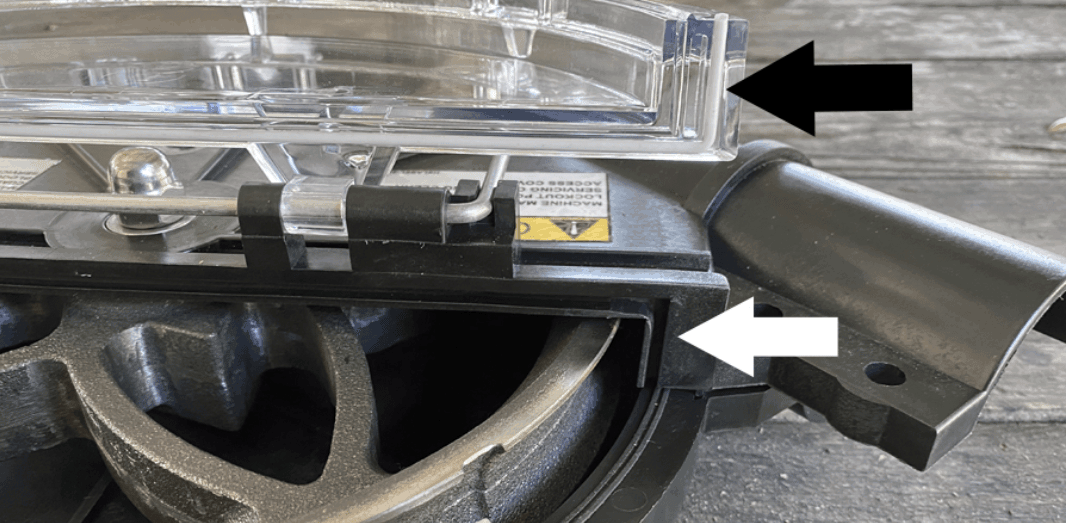

Not only does the transparent window allow for quick detection of a problem, but it also can be quickly opened by flipping the three cam latches. After removing any feed buildup, shutting the latches pulls the gasketed edges of the door tight against the housing, preventing any leakage.

E-Z Clean reduces maintenance as barn managers will no longer need to remove the chain tension at the drive unit before servicing the system, guess where the problem might be, or disassemble multiple corners for repairs. Click to learn more about E-Z Clean replacement corners or view an E-Z Clean video.