Costs of Bedding, Trailer Wash-out and Transport Losses in Market Weight Pigs

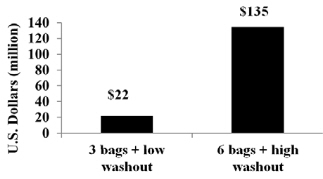

Based on 2011 figures, the highest estimate for annual costs of wash-out and bedding to the US pig industry was estimated at $135 million, according to Rebecca Kephart and others in the Iowa State University Animal Industry Report 2014.Summary and Implications

Trailers used to transport market weight pigs in the US are passively ventilated meaning airflow is dependent upon vehicle movement, thermal buoyancy and wind speed, according to researchers based at Iowa State University.

Research detailing the trailer micro-environment in the US is sparse. The amount of bedding on a trailer and the number of loads on it are believed to influence trailer microenvironment.

Using 2011 data for number of pigs transported, industry standards for density of pigs inside a trailer, and the average cost of bedding an estimated annual cost of bedding can be made. If new bedding were put on trailers after every load it is estimated to cost between $13 and $26 million dollars annually.

Again, using 2011 data and using national average cost of wash-out an estimated annual cost to wash-out the trailer can be made. Trailer wash-out adds between $8 and $108 million to the cost of bedding.

When the micro-environment exceeds a pig’s thermal comfort zone transport losses can result. Transport losses, the sum of dead on arrival and non-ambulatory, are difficult to estimate because non-ambulatory pigs are not tracked nationally. Dead on arrival are estimated to cost around $29 million annually.

Introduction

In the US, published research detailing the micro-environment inside trailers transporting market weight pigs is sparse. Additionally, studies from the European Union are difficult to transpose to the U.S. because of major differences in trailer designs. Trailers in the US are passively ventilated, meaning that airflow is dependent upon thermal buoyancy, the movement of the vehicle, and wind speed. Bedding levels may influence the trailer’s micro-environment by providing insulation and absorbing moisture from pig waste.

The Transport Quality Assurance (TQA) programme, published by the National Pork Board, states that '...[the] trailer should be washed, disinfected, and completely dried after being unloaded...[and] weather appropriate bedding [should be added]' (page 30 and 16 respectively; TQA)

The amount and number of times bedding is reused may result in an inappropriate trailer micro-environment that, in turn, may detrimentally affect transport losses. Transport losses are the sum of non-ambulatory (NA) and dead on arrival (DOA) pigs. Non-ambulatory pigs can include both injured and fatigued.

Transport losses are an economic and swine well-being challenge for the US swine industry.

Therefore, the objective of this study was to quantify the cost of bedding, trailer wash-out and transport losses in market weight pigs using data from 2011.

Methods

The following calculations provide a guide for bedding, trailer wash-out and transport loss predicted costs based on 2011 data for the US swine industry. The calculations can be manipulated to meet individual needs.

Bedding costs

Average number of pigs transported per trailer: According to TQA, market weight pig (pigs weighing between 113.4 and 136.1kg) should be given between 0.32 and 0.44 m2 per pig. In 2011, the National Agriculture and Statistic Service (NASS) estimated the average weight of market pigs was 124.7kg.

Pig density per trailer/ average floor space on trailers

= average number of pigs transported per trailer (71.3 m2 per trailer) / (0.32 m2 per pig)

= 222.8 pigs per trailer (71.3 m2 per trailer) / (0.44 m2 per pig)

= 162.0 pigs per trailer

(222.8 + 162.0) / 2

= 192.4 average number of pigs transported per trailer.

Loads of market weight pigs: The NASS reported 109,956,300 market weight pigs were transported to processing facilities in 2011.

number of pigs processed / average number of pigs per trailer

= loads of market weight pigs

(109,956,300 pigs) / (192.4 average pigs per trailer)

= 571,498.44 loads of market weight pigs

Bedding costs: Three-and six bags of bedding were chosen because three bags of bedding barely covers-and six bags completely cover the trailer floor. Wood shavings, based on field experience, are readily used and widely available.

Prices from several sources (bestwoodshavings.com, outdoorpros.com, camping.cs7warehouse.net, farm-home.com) were averaged to provide a cost for a 0.2m3 (22.7kg) bag of wood shavings. Each of these sources provided the cost for different sizes of wood shavings in ft3 so a conversion to m3 needed to be conducted:

(ft3 per bag) * (m3 per ft3) = m3 per bag

(8.5 ft3) * (0.028 m3 per ft3) = 0.24 m3 per bag

(9.5 ft3) * (0.028 m3 per ft3) = 0.27 m3 per bag

(11 ft3) * (0.028 m3 per ft3) = 0.31 m3 per bag

[(cost per bag)/ (m3 per bag)] *0.2 m3

= cost per 0.2 m3 bag

($7.00/ 0.24 m3) * 0.2 m3 = $5.83

($6.75/0.27 m3) * 0.2 m3 = $5.00

($14.14/0.31 m3) * 0.2 m3 = $9.12

($16.31/0.31 m3) * 0.2 m3 = $10.52

(sum of cost per bag) / (number of sources)

= average cost per 0.2 m3 bag

($5.83 + $5.00 + $9.12 + $9.12+ $10.12) / 5

= $7.84 average cost per 0.2 m3 bag of bedding

Annual cost of bedding trailers:

(average cost per bag) * (3 bags) * (number of loads transported)

= cost of using 3 bags

$7.84 * 3 bags * 571,498.44

= $13,442,000 annual cost of bedding trailers using 3 bags

(average cost per bag)* (6 bags) * (number of loads transported)

= cost of using 6 bags

($7.89) * 6 *571, 498.44

= $26,883,000 annual cost of bedding trailers using 6 bags

Trailer wash-out costs

For biosecurity reasons, TQA recommends washing out livestock transport trailers after each load. Practically, this involves the removal of all bedding followed by disinfecting the trailer per company protocol. With the highest ($190) and lowest ($15) fees reported (livestocknetwork.com), for using wash-out facilities in the US, the annual cost of wash-out can be estimated.

(lowest wash-out price) * (number of loads transported)

= lowest cost of wash-out

(571,498.44 loads) * ($15)

= $8,572,000 lowest cost of wash-out

(highest wash-out price) * (number of loads transported)

= highest cost of wash-out

(571,498.44 loads) * ($190)

= $108,585,000 highest cost of wash-out

The cost of wash-out is compounded by the need to re-bed the trailer after. The total cost of wash-out and re-bedding can be seen in Figure 1.

Transport loss costs

Non-ambulatory pigs are not recorded by the Food Safety Inspectors Service (FSIS). Therefore, for this report NA losses will not be included in transport loss costs.

Number of pigs Dead on Arrival (DOA) / load: Based on the number of pigs marketed, number of loads, and the number of DOA pigs in 2011 the number of DOA pigs per load can be calculated:

(percent DOA) * (number of pigs marketed)

= dead pigs

(0.15%) * (109,956, 300 pigs)

= 164,934.45 dead pigs

(number of dead pigs)/ (number of loads)

= dead pigs per load

(164,934.45) / (571,498.44) = 0.29 dead pigs per load

Cost per dead market weight pig: In 2011, NASS reported the average price per cwt (aka price per 100lbs. of pig or 45.4kg of pig) was $66.50.

The cost of each DOA (or average price per head) can be calculated from the cwt price and the average market pig weight:

(average weight of pigs marketed) * (price per

45.4 kg)

= Price per pig(124.7 kg) * ($66.50/ 45.4 kg) = $178 per pig

Assuming dead pigs are a loss, the annual cost of dead pigs can be estimated:

Cost of DOA pigs annually:

(number of dead pigs) * (cost/dead pig)

= cost of dead pigs

(164,934.45 dead pigs) * ($178/dead pig)

= $29,358,000 cost of DOA at the plant

Discussion

Using these calculations and 2011 data, it is predicted that bedding, wash-out and transport losses cost the US swine industry between:

- $13-and $26 million annually for bedding after each load

- $8-and $108 million annually for trailer wash-out after each load

- $29 million for DOA

However, the estimate for trailer wash-out is likely under budgeted as additional costs were not considered. These additional costs might include recycling water or lost income to truckers while wash-out occurs.

The cost of transport losses are potentially under-budgeted because non-ambulatory animals were not included.

Based on the most cost-prohibitive estimates (six bags of bedding on every trailer and washing out at the most costly facility after every load), wash-out and bedding costs the US swine industry $135 million annually.

Therefore, it is strongly advised that a cost-benefit analysis should be performed to determine whether, pig well-being is improved with trailer wash-out and reapplication of new bedding after every load.

The authors of this paper were Rebecca Kephart (Graduate Research Assistant), Anna Johnson (Associate Professor), Kenneth Stalder (Professor), Ted Huiatt (Associate Professor, Department of Animal Science, Iowa State University), Avi Sapkota (Graduate Research Assistant), John James McGlone (Professor, Animal Science, Department of Animal Science, Texas Tech University).

Acknowledgements: Thank you to the National Pork Board’s Pork Checkoff program for funding this research.

April 2014