Healthy piglets beyond the antibiotic age

Out with tradition and in with a new approach to preventing post-weaning diarrhoea in piglets – by minimising the anti-nutritional factors in soybean mealAntibiotics and high doses of zinc oxide have long been the usual course of action for controlling, preventing or reducing post-weaning diarrhoea (PWD) in piglets. But, as these traditional problem solvers are banned and phased out in more and more countries, farmers are having to consider other ways to relieve the symptoms of PWD. Low-protein diets, restricted feeding and the use of various additives are among them.

Alternatively, farmers could choose a completely different approach – to try to avoid PWD altogether by removing the components in piglet feed that are most likely to cause it. In soy-based feeds, these components are known as the anti-nutritional factors (ANFs).

Looking at piglet performance around the world, it is clear that piglets can only tolerate a limited amount of these anti-nutrients. However, various factors mean it is impossible to set a maximum level for ANF in piglet feed. Environmental issues such as climate control and the general health status of the piglets all impact their ANF sensitivity.

This leads to another important point – that piglets thrive better without ANFs in their diet, making them better able to cope with other stress factors during the post-weaning phase.

Prevention is better than cure

At Hamlet Protein, we have built our business around a manufacturing process that takes the best from vegetable proteins while reducing ANFs. When developing formulations for young animals, the objective is to give piglets the nutrients they need while avoiding the components that contribute to PWD. Today, this means it is possible to deliver soy-based products with similar digestibility and nutritional value to fishmeal and milk proteins.

To achieve this goal, knowledge of the undesirable components in soy – and how to find them – is vital. The list of ANFs is long. So here is a brief overview of the main ones relevant to piglet feed.

- Trypsin inhibitors (TI)

- Oligosaccharides – stachyose and raffinose

- Antigenic proteins – glycinin and β-conglycinin

- Phytic acid

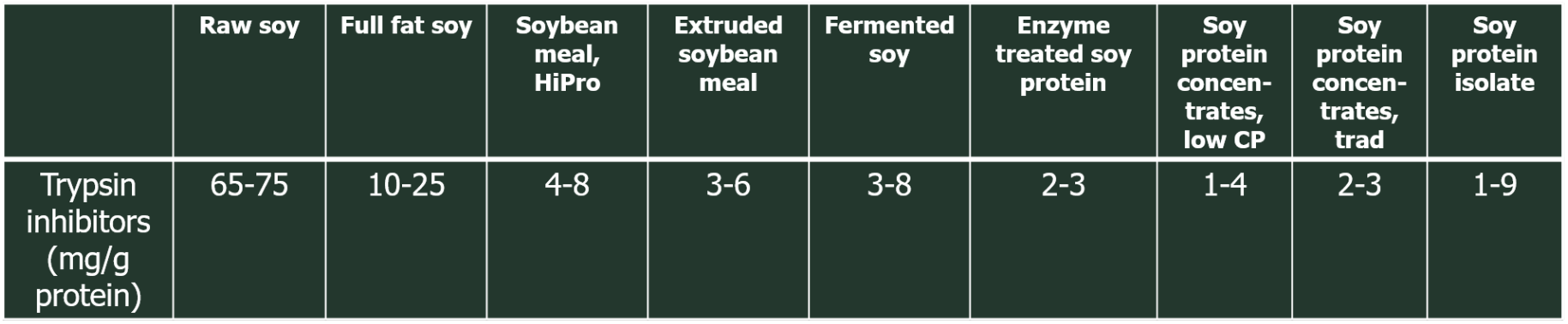

Trypsin inhibitor activity

Soy products typically have a high content of trypsin inhibitors (TI) (table 1), which develop naturally during plant growth – probably to protect the seed from plant-eating animals. When ingested, TI attach themselves to the protease enzymes trypsin and chymotrypsin in the small intestine, rendering them inactive. If the TI level is high, protease activity will be too low to ensure complete digestion of feed protein. These enzymes contain a relatively high proportion of essential amino acids, which are lost through the faeces. Even a relatively small loss of these essential amino acids will reduce feed conversion rates severely, as this then limits utilisation of other amino acids in the feed. The result is poor protein efficiency, less lean meat growth and loss of nitrogen to the environment.

In piglets, the gastrointestinal tract continues to develop until around 10 weeks of age, when growth and enzyme activity reach their maximum level. Protease enzyme activity in particular develops slowly, and piglets do not have the capacity to replace protease activity that is lost. This is the main reason for incorporating animal proteins and other specialised ingredients in piglet diets.

Analysing TI in soy products is demanding. For this reason, few laboratories offer this kind of analysis. Urease activity is often used as an indicator for TI level in soybean meal, but is an inaccurate method for use on specially treated soy products. When analysing TI levels, it is important to analyse TI activity, not just the mere presence of certain molecules. Molecular analyses indicate only the size of the molecules and nothing about their potential activity.

Oligosaccharides

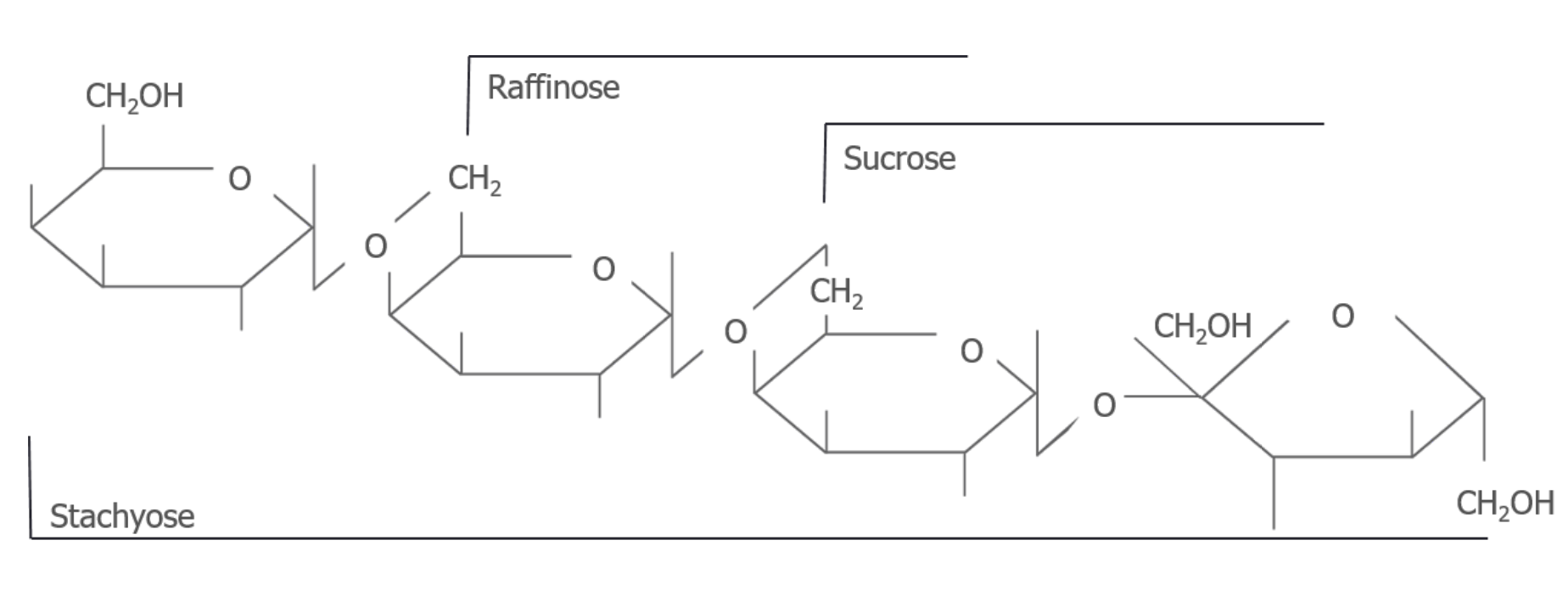

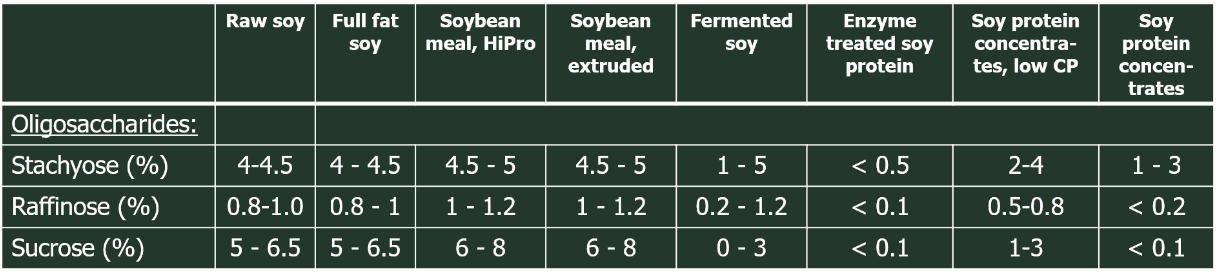

Soybeans have a natural sucrose content of 6-8%. This provides the basis for galacto-oligosaccharide development in the growing soybean plant. When one, two or three galactose rings are added to sucrose, the oligosaccharides raffinose, stachyose and verbascose develop, respectively (although the content of verbascose is negligible).

While fructo-oligosaccharides and mannan-oligosaccharides are considered prebiotic, this is not the case with galacto-oligosaccharides (GOS) in soy.

GOS are considered an ANF due to the bonds that link the galactose rings. Piglets, or any other monogastric animal for that matter, do not have the enzymatic capacity to split these bonds. In order to be absorbed, oligosaccharides must first be fermented by microbes. This fermentation is often initiated by gram negative bacteria in the small intestine and leads to gas formation, which can cause discomfort for the animal (as is very well known from pet food). At the same time, the bacterial count of E. coli, Lawsonia intracellularis and other pathogenic bacteria increases – this is why galacto-oligosaccharides are anti-nutritional.

Monogastric animals are furthermore unable to extract the energy from GOS. For this reason, the energy value of GOS-containing soy products is over estimated.

Antigens

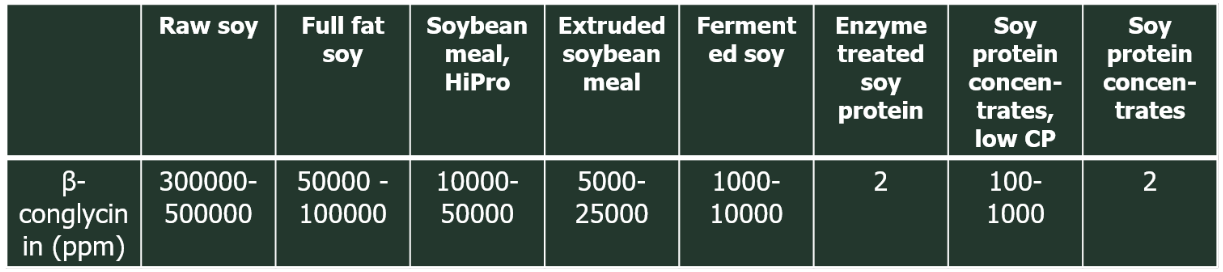

In feed production, soy is the legume with the highest content of antigenic protein. Up to 34 types of antigen have been reported. Of them, glycinin and β-conglycinin are the two that are normally seen as the major problem. These antigens cause antibody formation when injected into the blood stream of animals and humans. Β-conglycinin is also responsible for destroying the intestinal surface, with allergic reactions to the villi of the gut.

Pigs have the ability to adapt their immune system to β-conglycinin and build up tolerance. This explains why growers and sows can eat soybean meal without problems. Piglets, however, will suffer the allergic response in the gut until the immune system has adapted. This takes two to three weeks of exposure.

While antigens are heat sensitive, lengthy heat treatment is necessary to reduce them to sufficiently low level – a process that will cause the protein to denature and form Maillard reactions with the carbohydrates in soybean meal. Such overheating reduces the digestibility of the amino acids and their nutritional value. For this reason, the content of β-conglycinin in soy products varies widely depending on the drying and heat treatment processes used – drum and plate drying or toasting, for example. Air drying is necessary to minimise antigens without use of excessive heat treatment (table 3).

Phytic acid

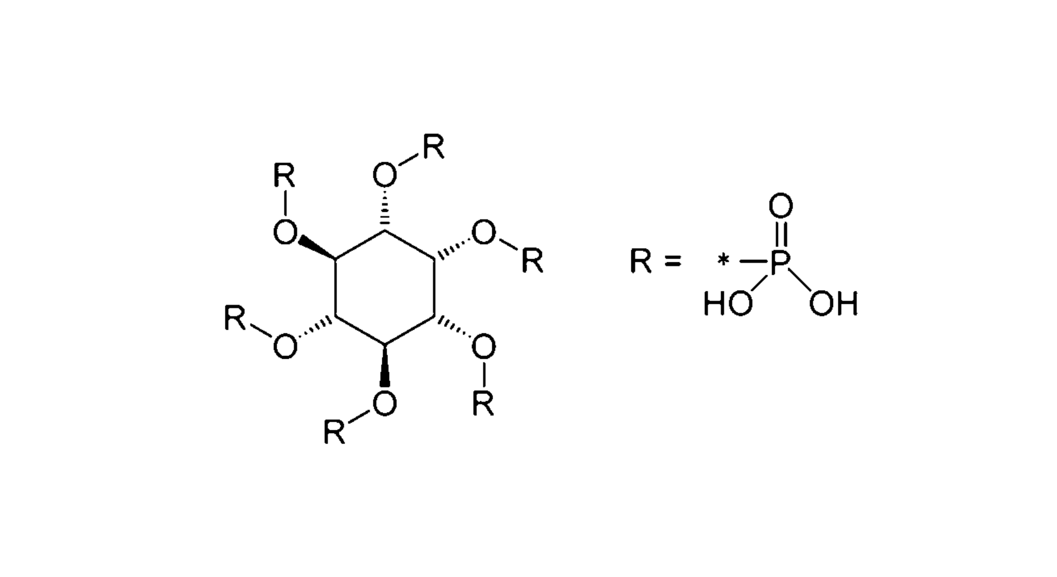

Of all the ANFs in soya, phytic acid is probably the best known, particularly for its ability to bind phosphorus so it is no longer bioavailable.

Phytic acid cannot be eliminated by heat treatment but must be broken down by the enzymatic activity of phytase. Today, phytase is commonly used in feed for this reason, even at doses two to four times higher than the dose normally required to digest phosphorus. The main reason for this is that phosphorus has become expensive, while phytases have dropped in price.

Phytic acid exists in many vegetable raw materials in addition to soybean meal. So, it makes good sense to ensure high phytase activity in the final feed, rather than focus on treating individual ingredients. This is true for piglets, but in broiler feed phytase treatment seems beneficial as their digestive system is not effective in utilising the phytase activity in the feed.

Note: Soy products have an average phosphorus content of 0.8%. In most products, 0.6% is bound in the phytic acid. *0.4 refers to a standard enzyme-treated product, 0.2 is a phytase-treated poultry product

Cost versus performance

At first sight, soy products with a low content of ANFs are slightly more expensive then the protein sources in simpler diets. But improved performance is likely to outweigh this extra cost. It is important not to underestimate the impact of poor health and medication on farmer earnings per piglet. At the same time, public opinion in many countries is turning towards piglet production with less medication and a higher standard of animal welfare. A growing number of countries have banned or plan to ban the use of zinc oxide to reduce the risk of post-weaning diarrhoea.

Another important factor to consider is that changes in feed composition during the pig’s lifecycle are a source of turbulence that may impact gut microflora and gut health in general. As grower and slaughter pig feed is typically a combination of cereals and soybean meal, an all-soy approach to piglet feed will support a smooth transition to later diets.

Feeding piglets with soy protein ingredients that are low in ANFs and high in digestibility ensures optimum utilisation of the nutrients in the feed. It also helps reduce the incidence and severity of post-weaning diarrhoea and the need to rely on antibiotics or zinc. Instead, farmers can look forward to higher performance and healthy, thriving piglets – an altogether more relaxing way to run their business.

| References | ||||

|---|---|---|---|---|

| Hans Christial Elbek Pedersen, | ||||

| (1986) | Studies of Soybean Protein Intolerance in the Pre ruminant Calf, | |||

| KeShun Liu, | ||||

| (1997) | Soybeans, |