Marketing Pigs

Pigs need to be sold at an optimum weight in order to maximise profit. Chad Paulk of Texas A&M University explains how to calculate the best weight in a Factsheet for Pork Information Gateway.Introduction

Marketing pigs is an important aspect to profitable swine production. Pork processors have developed marketing grids that value carcasses. These grids are specific to each pork processor with premiums based on carcass weight and leanness.

Although premiums depend on the pork processor, the overall trend is for processors placing more importance on carcass weight and importance on percent lean. Pigs need to be sold at an optimum weight in order to maximise profit.

Objectives

The purpose of this fact sheet is to help producers determine when to market groups of pigs and carry out the appropriate procedures when loading pigs out of the barn to optimise profitability.

After reading this document, a producer should be able to:

- Determine the optimum market weight for a group of pigs.

- Estimate the number of pigs in each weight range.

- Understand how to physically market the barn.

- At what weight to sell pigs?

Pork processors have specific requirements for pig carcass weights reported as 'Packer Grids'. A producer can utilise packer grids to determine the optimum market weight for a group of pigs. The optimum market weight is the average weight for a group of pigs where margin over cost is maximised.

Therefore, the producer needs to identify the market value and cost associated with raising and selling pigs to identify the optimum market weight. These will then be used to calculate the margin over feed and facility cost. The point at which any further increase in market weight will not pay for the cost of feed and facilities will be considered the optimum market weight.

Complete the following steps to determine the optimum market weight for a group of pigs.

1. Base value. The first value that needs to be calculated is the base value. The base value is the amount of carcass yielded from each pig multiplied by the carcass market price. Carcass market price is reported on a $ per cwt carcass basis. The following formulas are used to calculate the base value for a live pig.

- Base value = Pig live weight (lb) × carcass yield (%)× carcass base price ($/cwt)

- Carcass yield (%) = Hot carcass weight (lb) ÷ pig weight at the farm (lb)

2. Premium value. The premium value needs to be calculated next. This accounts for all price alterations compared to the base value. The premium value equals the difference in the gross value (price paid) and the base price.

In order to determine the premium value, previous marketing data from the packer should be used. Use the following steps to generate an equation which will estimate the premium value for a given weight. It is important to note that the body weight represents the average weight for a load of pigs.

- Collect data (i.e. market weight, base price [$/cwt carcass], sort loss, lean premium, gross value, any other price alterations) from the plant.

- Determine the premium value, $/cwt carcass. x = gross price ($/cwt before checkoff and trucking) - base market price

- Graph the premium value against market weight (Figure 1).

- Use computing data software to fit the data with a quadratic regression line.

- The quadratic equation will predict the premium value for each weight. f. This data will then be used in the market weight predictor.

3. Gross value. After calculating the base value and estimating the premium value, a carcass gross value needs to be collected for each weight group. Gross value is calculated as the following. Gross value = Base value ($/pig) + Premium value ($/pig)

4. Feed cost. The most important cost variable to consider is feed cost. It is dependent upon efficiency of gain. Feed per pound of gain can be estimated using production records or if this data is not available it can be estimated using the spreadsheet available by clicking here. Once at the website, select Marginal Return Spreadsheet. Once in the spreadsheet, select the 'Feed Efficiency Near Market' tab. After estimating the feed required per pound of gain, the following equation can be used to estimate feed cost:

- Feed cost = Feed efficiency (lb feed/lb gain) × Live body weight (lb) × feed cost ($/lb)

5. Facility cost. The next cost to consider is the facility cost. It represents how much it cost per day to house each pig.

Facility cost is calculated using the following equation:

- Facility cost = days required for growth × facility cost ($/pig)

6. Margin over feed and facilities cost. Lastly, the previously calculated gross value, feed cost and facility cost are used to calculate the margin over feed and facilities cost.

Incremental (difference in current weight group vs previous weight group) margin over feed and facilities cost should be calculated to determine the point where the value of any additional weight will no longer cover the costs of the feed and facilities. Therefore, the weight group with an incremental margin over feed and facilities closest to zero will represent the optimum weight pigs.

Market Weight Predictor

- A spreadsheet is available for use at the following web site: www.asi.k-state.edu/species/swine/ research-and-extension/marketing-tools.html

- Once at the web site, select KSU market weight predictor July 2014.

- Once in the spreadsheet select the 'Customized grid' tab.

- Inputs for 'Parameters for $/cwt premium' are derived from the previous developed equation (Step 2. Premium Value) to estimate premium value.

- Additional instructions are included on the website to assist in using the market weight predictor.

Which Pigs Are Ready for Market?

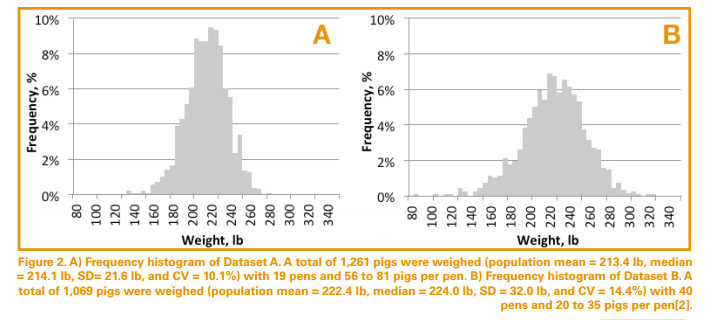

Individual pig weights vary within a barn. However, typically pig body weights approximate a normal distribution (Figure 2).

Therefore, estimating the mean and standard deviation of the population can be used to model the distribution of pig weights within a barn. This model can then be used to estimate the various weights of pigs within a population or the number of pigs in established weight groups. This information can then be used to determine when to market each group of pigs.

Estimating the Mean and Standard Deviation

7. Growth Models

Growth models can be developed by weighing pigs multiple times throughout the grow-finish period. This data can then be used to develop a growth curve for pigs in the system. This curve will estimate the average weight on each day.

8. Feed budgets

Barn entry and exit weights and estimated feed per pound of gain are used to develop feed budgets. Therefore, producers can monitor feed usage and estimate average barn weights based on the amount of feed used.

9. Sampling Barns

- Because pig body weight typically approximates a normal distribution, sub-sampling methods to predict the mean and standard deviation can be used.

- Sampling requires a scale and additional labor to weigh a subset of pigs.

- How to sample:

- Use a random number generator in Excel or draw numbers from a hat to randomly select 15 pens inside the barn.

- Weigh five pigs from each of the 15 pens. Weigh the easiest five pigs to move onto the scale. Do not select specific pigs from the pen to weigh. This may bias your sample.

- Calculate the mean and standard deviation of the 75 pigs weighed (Figure 3).

- Weighing fewer pigs will reduce the precision of your estimate.

How to Estimate Pig Weights in the Barn

- Estimate the mean and standard deviation as previously described.

- Insert the number of pigs, mean, and standard deviation into an excel spreadsheet (Figure 4).

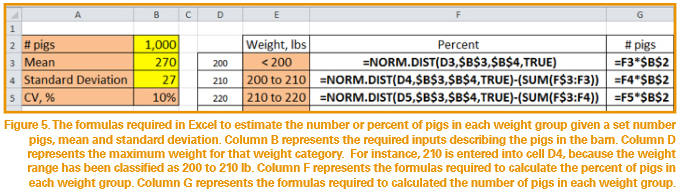

- To predict the number of pigs in each weight bracket, create a spreadsheet and enter the formulas demonstrated in Figure 5.

A similar spreadsheet is available for use at the following web site: www.asi.k-state.edu/ species/swine/research-and-extension/marketing-tools.html

Once at the web site, select 'KSU Weight Variation Estimates'. Once in the spreadsheet, select the 'market' tab.

Information on when to market pigs was derived from the Kansas State University Swine Research and Extension web site.

Sending Pigs to Market

Plan of action

1. Have a clearly defined plan of action.

- Make sure this plan abides by biosecurity protocols.

- More information on biosecurity can be found in the Transport Quality Assurance Handbook.

2. Define the team leader who makes the final decisions during the loading process, including whether or not to load or unload a specific animal.

- This person should be the same person who selected pigs for market or have great communication with the person who selected pigs

3. Make sure everyone knows their responsibilities.

4. Prior to load-out, mark pigs to be loaded onto the truck.

- Pigs must be clearly identified.

- Do not mark pigs too far in advance to prevent markings from fading

5. Two handlers work to sort and remove the correct pigs from the pen.

- It is important that only the selected pigs get removed from the pen.

- If an unmarked pig escapes the pen it should be returned to its pen and NOT loaded on the truck.

- It is recommended to move no more than three to five market pigs at a time.

6. The third handler moves them down the alleyway to the exit.

- Make sure no unmarked pigs are being moved.

7. The fourth handler moves them onto the chute and truck.

- Make sure no unmarked pigs are being loaded onto the truck.

8. If a delay occurs in loading pigs, be sure to communicate with everyone involved with the transportation process.

Facilities and Equipment

- Acceptable equipment for handling pigs

- Sorting board or bi-fold panel

- Plastic tattle/shaker paddle

- Nylon flag

- Matador’s cape

- Plastic ribbons on a stick

- Electric prod

- last resort tool; it should only be used when absolutely necessary.

- guidelines for use are outlined in the Transport Quality Assurance Handbook.

- Alleyways and doorways

- Alleyways should be three feet wide. Pigs should be able to walk side by side in the alley without resistance.

- Doorways should be at least the same width as the alleyways.

- Door should open completely.

- Avoid thresholds on the doorway floor.

- Ramps and chutes

- Ramps should be 20 degrees or less.

- Concrete ramps should have stair steps and nonslip surface.

- It is recommended that steps have a 2.5-inch rise and a 10-inch tread.

- Ramps should have cleats spaced eight inches apart.

- Ramps should be straight with no 90-degree turns.

- If possible, curves are preferred.

- Chute width should be between 32 and 36 inches.

- Chute width should not be wider than the trailer door.

- Covered chutes will help pig movement.

- Eliminate gaps between the barn and the chute. Can be done using a cushioned bumper dock system.

- Metal coated with epoxy is recommended for flooring.

Information on sending pigs to market was derived from the Transport Quality Assurance Handbook. Please refer to the TQA Handbook for additional information on pig handling and facility and equipment recommendations.

Summary

Marketing pigs is a critical process in swine production. This 'How-To' has provided calculations, tools and tips to help successfully determine when to market a barn of pigs to maximise profitability and how to conduct the process in the barn.

It is important to account for all factors that affect carcass value and production cost when determining market weights. Make sure to incorporate current price changes in processor grids and feed and facility cost. Marketing pigs at the right time and making sure the right pigs are loaded onto the truck are the keys to successfully marketing a barn.

December 2014

.PNG)