Performance of Evaporative Cooling Pads on a Swine Farm in Central Iowa

This study by Iowa State University found that evaporative cooling pads on a commercial breeding/gestation/farrowing facility in central Iowa showed good performance.Summary and Implications

Heat stress can lead to significant production losses for livestock. Production losses can take the form of slower rate of gain or poor reproductive performance in livestock systems.

While modern ventilation systems utilise elevated air velocity to cool the animals, conditioning the air via evaporative cooling is a viable option for heat stress relief.

While it is commonly thought that humid summer weather conditions in the upper Midwest are not suitable for use of evaporative cooling, this study found that evaporative cooling pads on a commercial breeding/gestation/farrowing facility showed good performance.

Temperature drops of 10-20°F were measured across the cooling pads.

Proper maintenance of the pads to ensure adequate water dispersion and even airflow was critical to maximising the pad cooling effectiveness.

Introduction

Summer conditions in the upper Midwest often exceed the thermoneutral zone of pigs. The summer design temperature for Iowa is 91°F/77°F dry bulb/wet bulb, which still offers about 10°F of potential drop with evaporative cooling.

Producers wish to reduce heat stress of their pigs through either direct or indirect cooling. Direct cooling of pigs includes drippers or sprinklers applying water to the skin of the pigs to cool through direct evaporation (similar to sweating, though pigs do not sweat). Indirect cooling of pigs utilises cooling the air entering or inside the barn. Systems like evaporative cooling pads and inlet (high-pressure) foggers are two examples.

Evaporative cooling pads have been used extensively in the Southwest and are gaining popularity in the Midwest. Cooling pads work by pulling air through a cardboard honeycomb material that is saturated with water. As the water is evaporated it cools and humidifies the air entering the barn.

This cool and humid air then increases convective heat loss from the animals in the barn compared to utilising air at ambient conditions.

Although requiring more equipment and management than a simple tunnel ventilation system, cooling pads offer the opportunity to both reduce heat stress on animals during the hot portion of the day and to cool the barn down quickly in the evening to allow for maximum recovery time for the animals.

The objective of the study was to characterise the operational performance of an evaporative cooling pad system at a commercial swine farm in central Iowa.

Materials and Methods

A modern 4,300-head breeding/gestation/farrowing facility was installed with temperature/relative humidity (RH) sensors before and after the evaporative cooling pads. Temperature and relative humidity were also monitored inside the barns.

Data were collected during the summer of 2012 and a hot spell in late summer 2013.

Results and Discussion

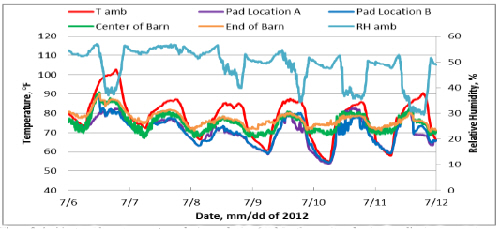

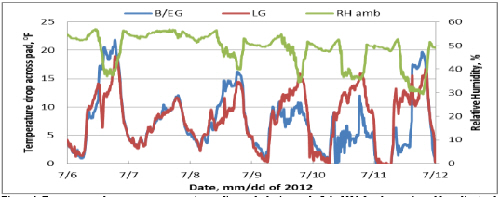

A sample of the data from a period in July of 2012 is shown in Figures 2 and 3.

Figure 2 shows the temperatures measured immediately after the pad, in the centre of the barn, and at the opposite end of the barn, along with the ambient temperature and RH.

Looking first at the ambient conditions, we note that as the temperature rises during the day, the RH decreases, which provides considerable temperature reduction potential during the hottest part of the day.

This is evidenced by Figure 3, where the temperature drops measured across the pads in two gestation barns are shown. Temperature drops of 10 to 20°F during the day were common. The effect of the cooling pads is most dramatic on the first day shown in Figure 2 (7/6) where the ambient temperature wasat 100°F for several hours but the barn temperatures only reached 85°F.

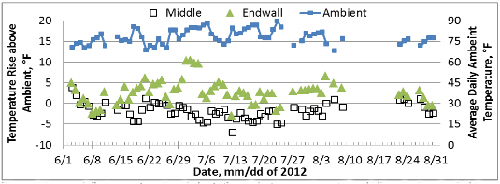

Figure 4 shows the monitored days where the average daily ambient temperature exceeded 68°F and the pads were running. On these days, the average daily temperature at the middle of the barn is usually 0° to 5°F below the ambient temperature and the end of the barn (near the exhaust) is typically less than 5°F above the ambient conditions.

These small differences compared to ambient conditions across an entire day are critical to reducing heat stress on the animals.

Combined with the large temperature drops during the hot portion of the day (discussed above), the pads not only offer a method to reduce heat stress during the day but also a method for cooling the barns down in the evening to give the animals a recovery period before the next heat stress event.

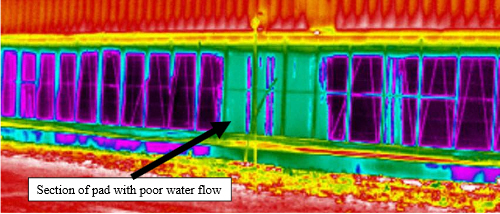

Maintenance of the pads and equipment is critical to their performance. Depending on the system design and water quality at the farm, producers can often have pipe clogging problems and growth of biological material in the pads. Figure 5 shows a thermographical image of the cooling pads where a section of the pad is not receiving adequate water flow due to clogged opening in the pipe.

This section will not cool the incoming air as effectively (if at all) as the rest of the pad and will reduce the overall effectiveness of the pad on indoor environment.

The authors of this paper - published in Iowa State University Animal Industry Report 2014 - were John Stinn (Graduate Research Assistant, Agricultural and Biosystems Engineering and Hongwei Xin (Professor, Agricultural and Biosystems Engineering and Animal Science).

Acknowledgements: The study was supported by a research grant from the Iowa Pork Producers Association and cooperation of the swine producer in allowing the researchers access to the production facility and animal production data.

Further Reading

You can see other papers in the Iowa State University Animal Industry Reports 2014 by clicking here.

May 2014