Danish Pig Research Centre Annual Report 2012: Nutrition 2

The Pig Research Centre reports on its latest work on fermented rapeseed meal, commercial diets, particle size and xylanases for weaners and for finishers, restricted feeding, liquid versus dry, rye, benzoic acid and conjugated linoleic acid.Feeding Weaners

Fermented rapeseed cake

The inclusion in weaner feed of fermented rapeseed cake produced by the Fermentationexperts A/S was investigated. The purpose of fermenting rapeseed cake is to improve the digestibility of protein and reduce the content of anti-nutritional factors.

Results revealed that fermented rapeseed decreased production value by seven to nine per cent compared with soybean meal (15 per cent inclusion) or rapeseed cake (11 per cent inclusion) to weaners (9-30 kg live weight). Weaners fed fermented rapeseed cake had a poorer FCR and lower gain, and no effect was observed on health. Production value did not differ between control and the group fed rapeseed cake.

To be able to cover the reduction in productivity, the diet with fermented rapeseed must be DKK11 cheaper per 100 feed unit (FUgp).

The reduction in productivity can be attributed to several factors:

- Degradation products formed from glucosinolates in the rapeseed cake used, which adversely affect pig growth.

- The included digestibility rate of crude protein of 85 per cent declared by the manufacturer was too high, thus the pigs experienced a protein deficiency. Normally, digestibility of rapeseed cake is 76 per cent (nine percentage units lower).

The project was fnancially supported by the Innovation Act in cooperation with Aarhus University, the University of Copenhagen, Scanola, Den lokale Andel – journal no. 3412-07-01960.

Commercial diets

Commercial weaner diets purchased in Mid- and East Jutland (season 2011/2012) from the following producers were compared (production index written in parenthesis):

- DLG (105)

- Danish Agro (100)

- Vestjyllands Andel (112)

- Hornsyld Købmandsgård (104)

Each feed producer nominated a starter diet and a weaner diet for the trial. All diets were formulated pursuant to the current recommendations for ‘protective’ diets (2011).

Diets from Vestjyllands Andel yielded a significantly higher production value than the other diets in the trial. The diets from DLG yielded a significantly higher production value than the diets from Danish Agro.

If choosing the diets from Vestjyllands Andel, a pig producer can pay DKK30, 54 and 35 more per 100kg for these diets than for the diets from DLG, Danish Agro and Hornsyld Købmandsgård and still achieve the same production value.

Grinding and xylanases

The effect of grinding and the addition of two xylanases on weaner productivity were investigated. Two different degrees of grinding (70 per cent and 50 per cent particles below 1mm) and two xylanases (carbohydrate-splitting enzymes) from Danisco (BS3 Xylanase and Porzyme 9302) were studied. Weaners in these trials were fed meal feed from eight to 30kg.

Weaners fed fnely ground feed (index 100) versus coarsely ground feed (index 94) had a significantly higher production value. Daily gain was approximately three per cent higher and FCR around three per cent better. The lowest frequency of treatment for diarrhoea was seen in the group fed coarsely ground feed. However, culling rates in this group were also higher, which may be attributed to the fact that more small pigs were moved from the pens.

BS3 Xylanase had a significantly positive effect of two to three per cent on gain and FCR. This led to a higher production value than pigs given feed without xylanase. The costs of adding BS3 Xylanase were fully covered by the improved productivity. No significant effect was observed from adding Porzyme 9302. The addition of xylanase had the same effect on productivity regardless of grinding.

The project was financially supported by the Pig Levy Fund and the GUDP programme under the Danish Ministry of Food, Agriculture and Fisheries – journal no. 3405-10-0098.

Feeding of Finishers

Restricted ad lib feeding

When finishers are fed dry feed ad lib, particularly when fed from tube feeders, there is a risk that the feed intake towards the end of the growth period gets so high that especially castrates start depositing fat instead of protein.This may reduce FCR as well as lean meat percentage. On two farms where pigs were fed dry feed from tube feeders, Pig Research Centre studied the effect of restricted feed intake towards the end of the finisher period.

Research revealed that restricted ad lib feeding improved lean meat percentage but not FCR and the increased lean meat percentage was offset by a lower daily gain. Impacts on productivity of restricted feed intake:

- lean meat percentage improved by 0.4 to 0.6 percentage units

- daily gain dropped by 35 to 70g a day

- FCR was reduced by up to 0.03 FUgp/kg.

It is therefore not recommended to practise restricted ad lib feeding in tube feeders for either females nor castrates in the last part of the finisher period unless the wish is to optimise lean meat percentage while at the same time accepting that it takes longer to reach optimum slaughter weight.

Liquid or dry feeding

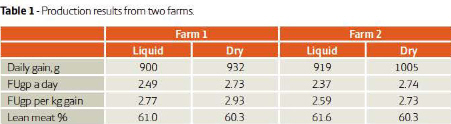

On three farms, finishers fed restricted liquid feed were compared with finishers fed dry feed ad lib. Both feeding systems were established in the sections. At the time of writing, the study was finished on two farms.

Both farms witnessed improved FCR and lean meat percentage but also a lower daily gain, among the pigs fed liquid feed (Table 1 ). Both farms produced females as well as castrates. On farm 1, pens housed mixed genders and on farm 2, pigs were housed according to gender. On farm 2, the greatest difference was seen in castrate productivity, which was attributed to a higher daily feed intake among the castrates in the last part of the finisher period when they were fed dry feed ad lib. This shows that castrates benefited the most from restricted feeding.

The project was financially supported by the Pig Levy Fund and the EU and the Rural District Programme under the Danish Ministry of Food, Agriculture & Fisheries – journal no. 3663-D-10-00460.

Investment costs and operating costs must also be considered when comparing production economy between liquid feed and dry feed. The place unit in liquid feeding facilities is bigger and thereby more expensive due to a bigger trough and higher costs for heating the room, maintenance and additional amino acids. These additional costs must be set against the profit obtained through improved productivity.

On farm 3, the trial includes female and male pigs. Preliminary results reveal that female pigs perform best on liquid feed, while male pigs perform best on dry feed.

The activities were financially supported by the EU and the Rural District Programme under the Danish Ministry of Food, Agriculture and Fisheries. Journal no. 3663 D 09 00354.

Rye

The effect of increasing inclusion of rye in pig feed is currently being investigated with and without the addition of carbohydrate-splitting enzymes.

Preliminary figures reveal that feed intake in finishers drops when feed contains 40 per cent rye resulting in a lower daily gain but a higher lean meat percentage. Preliminary results show no significant effect on FCR of a high inclusion of rye. The addition of carbohydrate-splitting enzymes to a rye-based diet does not seem to improve the feed value of rye.

(Photo: Morten Haastrup, Knowledge Centre for Agriculture)

The project was financially supported by the GUDP Programme. Journal no. 3405 10 0098.

Benzoic acid

Research has demonstrated that the addition of one per cent benzoic acid to finisher feed improves finisher productivity. However, as benzoic acid is expensive, the costs were not fully covered by the improved productivity.

The effect of different indusion rates of benzoic acid in finisher feed was therefore investigated (trial report 947): 0.5 per cent, 1.0 per cent and a phase-feeding diet with 1.0 per cent up to 70kg followed by 0.5 per cent until slaughter.

Results showed that the addition of 0.5 per cent benzoic add improved productivity as much as the addition of 1.0 per cent.The same level of productivity was observed in the group with phase-feeding (Table 2).

Benzoic acid improved daily gain and FCR but reduced lean meat percentage.

Once the price of benzoic acid was included in the production economy, a profit was only achieved with inclusion of 0.5 per cent benzoic acid. Part of this profit came from the improvement in gain. It is therefore essential that pig producers are able to utilise the increased gain in the production in the form of either an increased slaughter weight or number of pigs produced annually.

The greatest effect of benzoic acid on productivity was observed in the first half of the growth period. This is the period with the lowest feed intake, and it is therefore more profitable to add just 0.5 per cent benzoic acid during phase-feeding in the growth period until approx 70kg.

In another trial, the effect of benzoicacid on odour and ammonia emissions was investigated.

The project was financially supported by the EU and the Rural District Pro gram me under the Danish Ministry of Food, Agriculture and Fisheries. journal no. 3663-D-09-00365.

Conjugated linoleic acid (CLA)

CLA is naturally occurring in dairy products and meat, and several trials have revealed positive effects on daily gain, FCR and lean meat percentage. Pig Research Centre also investigated the effect of increasing inclusion of CLA (Lutalin™ with 60 per cent CLA) in feed for finishers.

In this trial, finishers were fed CLA from around 62kg live weight, and the trial comprised five inclusion rates (0 to 0.5 per cent CLA). The inclusion of 0.5 per cent CLA from around 83kg was also investigated.

Lean meat percentage increased when finishers were fed ClA from 62kg until slaughter at around 111kg and the effect increased as the inclusion rate increased (from 0 to 0.5 per cent). Lean meat percentage was also positively affected, regardless of whether the pigs were fed CLA from 62 or 83kg. FCR remained the same regardless of inclusion and duration of the inclusion of CLA. However, the improvement in lean meat percentage was offset by a lower daily gain when the pigs were fed CLA. Consequently, there was no financial benefit in adding CLA to finisher feed, irrespective of inclusion and duration.

In conclusion, there is no profit in adding CLA to finisher feed with the current settlement for lean meat percentage.

The project was financially supported by the EU and the Rural District Pro gramme under the Danish Ministry of Food, Agriculture and Fisheries. journal no. 3663-D-09-00354.

May 2013