Farrowing Alternatives for Small Farms: Insulated Tents for Sows and Pigs, Year One

Insulated yurts (tents) have been tested by Iowa State University as a bedded, crate-free farrowing environment for family farms in Iowa. Pre-weaning piglet mortality was higher than in commercial systems with farrowing crates, particularly during the warmer summer months in this initial study.Summary and Implications

Farmers raising pigs for niche markets are usually prohibited from using farrowing crates and must provide bedding and greater space per sow than typical commodity production.

Because current consumer expectations dictate that pigs be produced year-round, crate-free farrowing options for cold weather are necessary and many niche pork companies will not accept new producers into their programme unless they agree to farrow pigs during winter months.

Several crate-free farrowing systems for cold weather have been demonstrated in Iowa, however those alternatives generally require a permanent, well-insulated structure and/or tremendous amounts of energy to provide a suitable environment for the newborn pig. Beginning farmers often struggle to include livestock on their farms due to lack of investment capital and long-term leases or other forms of land permanency.

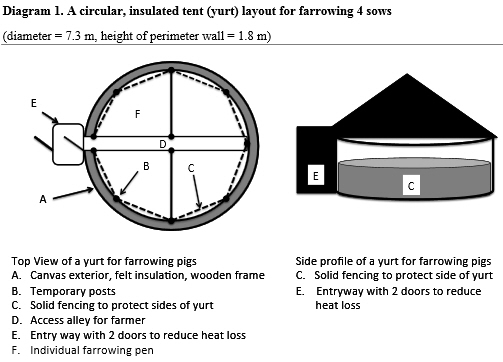

A yurt is a circular (7.3 metres in diameter), insulated tent. It is a semi-permanent modular structure that can be modified to farrow small groups of pigs. Widespread adoption of commercially manufactured yurts for farrowing pigs in Iowa is unlikely but the pig management strategies and techniques developed during the course of this project will inform the continued on-farm refinement of crate-free farrowing systems for cold weather.

Introduction

Incorporating livestock into farms is often a key aspect of improving the resiliency and sustainability of farms. Pigs fill an important niche in farm-scapes and have long been a major component of financially sound family farming in Iowa. Pork production for niche markets can be less capital-intensive and thus is an attractive option for some beginning farmers.

Farmers raising pigs for niche markets are usually prohibited from using farrowing crates and must provide bedding and greater space per sow than typical commodity production.

Because current consumer expectations dictate that pigs be produced year-round, crate-free farrowing options for cold weather are necessary and many niche pork companies will not accept new producers into their program unless they agree to farrow pigs during winter months.

Developing versatile, low cost alternatives for farrowing small groups of sows in a bedded, crate-free environment during cold weather is a critical step towards achieving the larger goal of increasing the resiliency of Iowa agriculture through diversified crop and livestock farms owned and operated by young farmers.

Yurts are traditional structures that have sheltered nomadic peoples of the Asiatic steppes for centuries and are still common throughout Mongolia as year-round dwellings.

The modern yurt consists of a wooden frame covered with insulating layers of felt. The structure is then encased in a canvas tarp. The floorless structure rests directly on the soil and is held in place using tension cables and perimeter blocking. Several North American manufacturers market yurts to the American consumer in do-it-yourself kits. With slight modifications this structure may be suitable for farrowing small groups of sows during cold weather.

Because of their simple construction, mobility and adaptability to crate-free farrowing, yurts may be an attractive option for beginning farmers.

This project will examine the feasibility of insulated yurts as a bedded, crate-free farrowing environment for family farms in Iowa. Widespread adoption of commercially manufactured yurts for farrowing pigs in Iowa is unlikely but the pig management strategies and techniques developed during the course of this project will inform the continued on-farm refinement of crate-free farrowing systems for cold weather.

Materials and Methods

One insulated yurt kit was purchased from a domestic manufacturer (Colorado Yurt Company, Montrose, Colorado) in the spring of 2012. The yurt was erected at the Allee Demonstration Farm, Newell, Iowa and modified to house pigs. Solid penning material was used to protect the fabric sides of the yurt and otherwise subdivide the interior space into four farrowing spaces as well as a common area for feeding and watering. The yurt used for this project was a circular (7.3 metres in diameter) model with a exterior wall height of 1.8 metres.

This is an initial report of a two-year study. In total, four groups of four sows or gilts will farrow during winter and summer seasons.

For each group, bred sows or gilts that were due to farrow within three days of each other were delivered to the Allee Demonstration Farm several weeks prior to farrowing. Gestating sows were housed as a group on a concrete feeding floor with open-fronted building. Approximately 24 hours prior to farrowing, the group of sows were moved into the yurt, where they were each provided an individual farrowing space. Creep areas with heat lamps were constructed to provide supplemental heating for young pigs.

Feeding and watering occurred within a communal space within the yurt. Following farrowing, sows were given full access to feed, preventing aggression usually associated with group feeding of sows.

During gestation, sows were provided corn stalk bedding.

Wood chips were used as bedding in the yurts to reduce fire risk and encourage liquid movement away from the young pigs. Individual pen dividers were removed approximately 10 days after farrowing and the four sows and litters were subsequently managed as one group until weaning at six weeks of age.

Throughout the project, energy inputs, bedding use and pig performance were measured and recorded. Internal and external thermal conditions were also recorded using HOBO®Pro v2 data loggers (Onset Computer Corporation, Bourne, MA).

This report summarises results from the first summer farrowing (15 August to 27 September 2012) and the first winter farrowing (8 February to 22 March 2013).

Results and Discussion

A work crew of five men built the yurt structure in about eight hours. Another 40 hours of labour were needed to install pens, gating, bedding, feeders, waterers, and electrical utilities. Initial costs of the yurt kit and materials needed to modify it for pig production was approximately $14,000.

Table 1 summarises pig production and labour for the first summer farrowing and the first winter farrowing. The dates for summer and winter farrowing groups were selected with the intent of farrowing pigs during weather extremes — the hottest part of summer and the coldest part of winter.

| Table 1. Production summary for summer and winter farrowing groups housed in a yurt at the Allee Demonstration Farm, Newell, Iowa |

||

| Summer 2012 | Winter 2013 | |

|---|---|---|

| Pregnant sows or gilts | 4 | 4 |

| Live pigs born | 48 | 48 |

| Pigs weaned | 30 | 35 |

| Pre-weaning mortality, % | 35.7 | 27.1 |

| Labour, hours | 144 | 243 |

| Summer = 15 August 2012 – 27 September 2012 Winter = 8 February 2013 – 22 March 2013. |

||

Although pre-weaning mortality for these farrowings were much larger than typical in the US pork industry, performance was similar to other crate-free farrowing systems.

Ambient temperature within the yurt was consistently 10 to 12°C warmer than the outside temperature during winter. The lowest interior temperature during the first winter farrowing was 18.3°C, and sows were generally quite comfortable inside of the yurt during winter.

The heated creep areas were used by the young pigs throughout lactation. Initially, sufficient heat lamps were provided to achieve a temperature near 35°C within the creep area; as the pigs grew larger, some heat lamps were removed.

Thermal conditions were more variable during summer. Providing sufficient air movement through the yurt to keep sows cool during very hot days was extremely challenging.

The interior temperature of the yurt was only 1–2°C cooler than the exterior temperature during summer. Using water to cool sows on bedding can create challenges for the young pigs, even if dry, warm creep areas are provided. The sows were generally more restless during the summer farrowing and as a result pre-weaning mortality was 10 per cent higher during summer than in winter. This is a trend that has been observed in most crate-free farrowing systems in Iowa.

The yurt is a modular solution for farmers seeking an insulated space to farrow a small group of sows during cold weather. Although the cost of a commercially available yurt kit is prohibitive to widespread adoption of this alternative, it is likely that a more economical version could be built from recycled, locally sourced materials.

Pig management strategies and techniques developed during this project will inform the continued refinement of crate-free farrowing systems for cold weather.

The authors of this paper - published in Iowa State University Animal Industry Report 2014 - were Peter J. Lammers (Assistant Professor, Department of Agriculture, Illinois State University, Normal, Illinois), Jay D. Harmon (Professor, Department of Agricultural and Biological Engineering), Lyle Rossiter (Farm Superintendent, Allee Demonstration Farm), Mark S. Honeyman (Professor, Department of Animal Science).

Acknowledgements: This project was supported by the Hatch Act, State of Iowa Funds and the Leopold Center for Sustainable Agriculture.

Further Reading

You can see other papers in the Iowa State University Animal Industry Reports 2014 by clicking here.

May 2014