Feed predictability starts here

Same quality. Every batch. Every time.Hamlet Protein ensures consistently low levels of antinutritional factors (ANFs) in every batch – helping prevent digestive issues, reduce oxidative stress, and support growth.

Soybean meal (SBM) is rich in protein and has an ideal amino acid profile, making it an excellent choice for supporting animal growth. As a result, SBM is the most commonly used protein source in pig and poultry diets. However, SBM contains antinutritional factors (ANFs) such as trypsin inhibitors (TIA), β-conglycinin (β-con), and galacto-oligosaccharides (GOS), which reduce digestibility and cause intestinal damage, oxidative stress, inflammation, and diarrhea:

- TIA inhibits the activity of trypsin, an enzyme involved in the digestion of proteins and hereby reducing the digestibility of all the proteins present in the diet, not only the proteins from SBM. Undigested protein serves as a substrate for microbial metabolism in the hindgut, leading to the formation of fermentation products that can affect animal growth and performance.

- β-con is an allergenic storage protein found in soybeans, which causes intestinal damage, oxidative stress, inflammation, and diarrhea in young pigs.

- GOS such as stachyose and raffinose cannot be digested by pigs due to the absence of α-galactosidase enzymes. As a result, these oligosaccharides pass into the hind gut, where they are fermented by gut bacteria, increasing the risk of diarrhea. Additionally, undigested GOS exert an osmotic effect in the small intestine, resulting in abnormally watery digesta that accelerates feed passage. This leads to reduced digestibility and nutrient absorption, ultimately impairing growth performance.[1]

The presence of these ANFs limits the inclusion of SBM in diets for young animals.

How Hamlet Protein removes ANFs

Since the 1990s, Hamlet Protein has been a trusted leader in specialty soy protein with a strong focus on delivering consistent high-quality products.

What sets Hamlet Protein apart is our patented enzymatic process and gentle heat treatment specifically designed to minimize ANFs without compromising protein availability. Reducing ANFs to levels that young animals can tolerate allows them to fully digest dietary protein and obtain its nutritional value.

Our process is based on continuous flow, where soy, water and enzymes are precisely mixed and co-processed under controlled, optimal conditions. After enzymatic treatment, the drying process operates at temperatures that effectively deactivate all enzymes and thereby stabilizes the product.

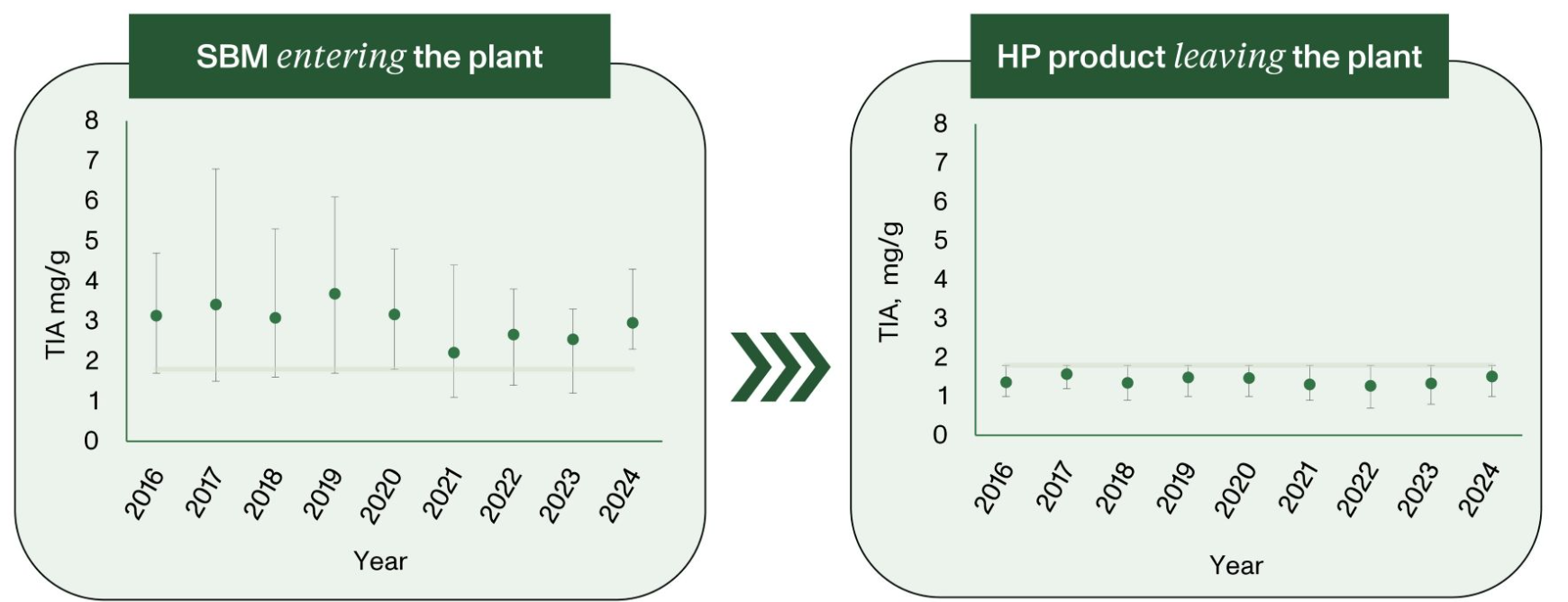

Since each shipment of SBM varies in quality, production parameters are adjusted to produce a standardized product (Figure 1). Just like nutritionists will adjust their matrix to account for changing nutrient values of the purchased ingredients and produce stable quality feed. This means you do not have to worry about batch-to-batch variability or manual matrix tweaks.

To learn more about how our process can guarantee consistent low ANF levels, contact us to request our Optimization Datasheets.

Hamlet Protein controls and delivers consistent quality, despite the natural variability of ANF in soybean meal

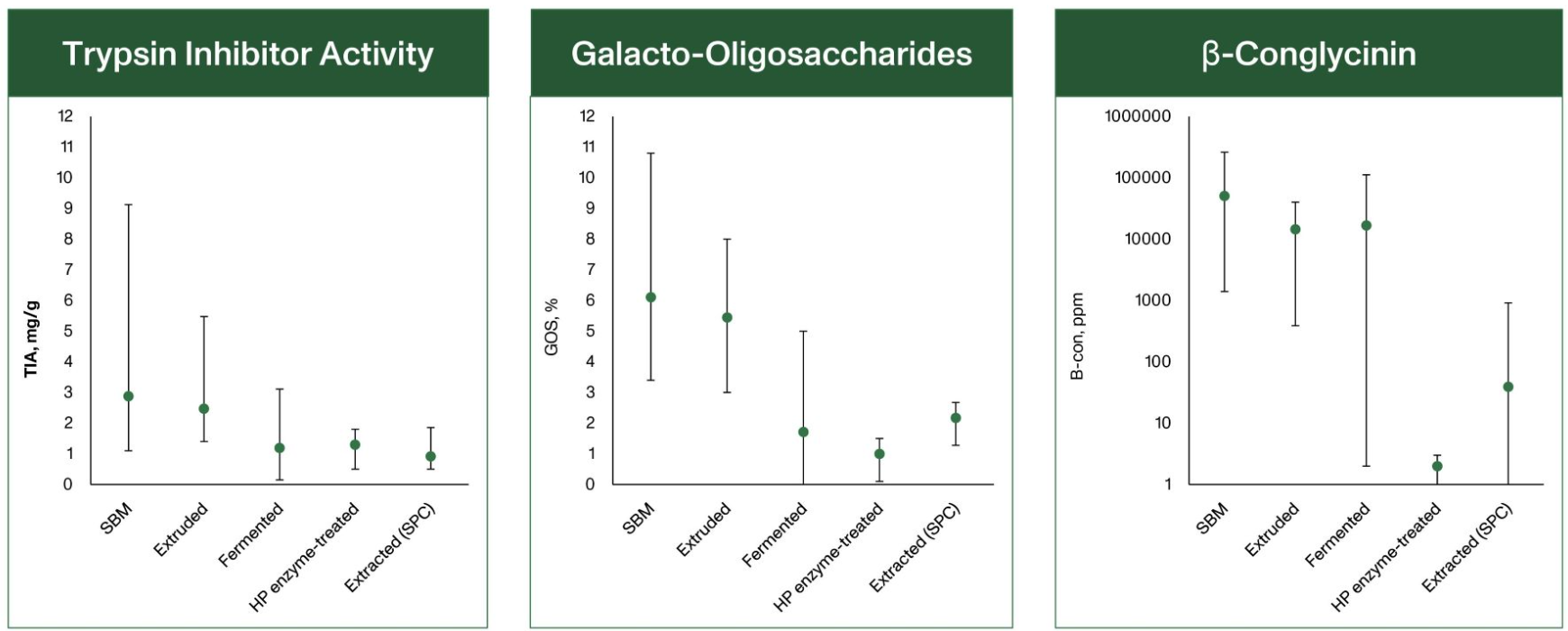

Soybean meal and soy protein products vary greatly in the content of nutrients and ANFs (Figure 2, SBM). The nutrient content and quality of soybeans vary based on factors such as soybean cultivar, growing and harvesting conditions, and processing methods in the crushing plants. This variability often forces nutritionists to tweak feed matrices.

In addition to our proprietary process, Hamlet Protein continuously monitors and controls every stage of production, guaranteeing consistency regardless of the variations in ANF contents in our raw materials (Figure 2, HP enzyme treated).

Our quality program allows us to put a specification on our ANF levels and consistently meet the specified levels. Hamlet Protein measures all three ANFs in our laboratory, which is a unique strength of our quality control.

Combat weaning challenges with a reliable protein source

Weaning is particularly stressful for piglets, as they are separated from their mother and transition from sow milk to cereal-based diets with a variety of plant-derived ingredients. This period also involves mixing piglets from different litters. As a result, weaning is known to induce oxidative stress and increase the blood concentrations of acute phase proteins.

When SBM is included in diets, the significant variability in its composition must be considered when formulating feed. This is particularly important because ANFs in SBM and other processed soy products will reduce overall digestibility, cause intestinal damage, oxidative stress, inflammation, and possibly diarrhea.

To mitigate the variability in nutrient content and ANFs found in SBM and other processed soy products, Hamlet Protein products are an excellent choice, ensuring consistent diet formulation for weaners. Hamlet Protein products can be used all year round during the sensitive early phase of young animals to prevent digestive issues, promote growth, and serve as a safe, high-quality alternative to variable protein sources like SBM. Additionally, feeding Hamlet Protein products to weaned piglets has been shown to reduce oxidative stress and inflammatory processes compared to diets containing untreated SBM.

The early development of the digestive system in piglets and other young animals is crucial to lifelong performance. Do not challenge an already challenged digestive system, focus instead on supporting it and give the animal a healthy start by using a consistent and high-quality product.

With over 30 years of expertise and a commitment to precision, Hamlet Protein sets the standard for consistent, high-quality soy protein solutions.

To learn more about how Hamlet Protein can support your feeding program, reach out to your local Hamlet Protein representative.

[1] References available upon request.