How to generate savings in swine feed: Re-validate and adjust nutritional value of methionine sources

Methionine functions in the metabolism

Methionine's role in the body goes beyond protein synthesis. One of the most important roles of methionine is being the first amino acid for the formation of the polypeptide chain essential for building body protein. Methionine is the precursors of different molecules that have a role for the immune system, antioxidants, lipid oxidation, transcription activation, and cell proliferation. Therefore, how we balance dietary methionine can greatly influence the growth and health of the pig. Methionine is the third limiting amino acid in typical diets for swine. The inclusion of feed grade supplemental methionine sources in the formulation of pig diets is, therefore, common and overlooked. As nutritionists, it is important to re-validate the nutritional value of methionine sources and adjust current nutritional practices for maximizing profit.

Scientific research

Sources of supplemental methionine used to balance swine diets are DL-methionine (99%), DL-2 hydroxy-4-methylthio-butyrate acid, also known as MHA (methionine hydroxy analog) free acid (MHA-FA; 88%) or its calcium salt (MHA-Ca; 84%), and L-methionine (99%). A significant amount of research has been dedicated to dose-response trials to estimate the relative bioavailability of MHA compared to DL-methionine where numerous studies have reported average bioavailability near 65%. For instance, based on nitrogen retention as response criteria, the bioavailability of MHA-FA and MHA-Ca compared to DL-methionine on a product-to-product basis was 65% (Kim et al., 2006) and 63%, respectively in growing pigs (Facts&Figures No. 1496). One of the reasons for the lower bioavailability of MHA-FA is due to the slower absorption throughout the digestive tract associated with more exposure to microbial degradation in the small intestine, and less available for absorption (Malik et al., 2009).

Trial design

Dose-response trials can be difficult and costly to conduct, especially under commercial conditions where the number of replications can be a constraint. A simplified validation approach is to replace 65 parts of DL-methionine with 100 parts of MHA on product-to-product basis in pig diets and compare pig performance responses. Therefore, a study was conducted in 2019 on a commercial research farm in the Midwest of the US (Facts&Figures No. 14143). A total of 1,296 weaned pigs were evaluated in a 49-day performance study with four phases (16 pens per treatment, 27 pigs per pen). Pigs were fed three diets: 1) A methionine-deficient diet (70% of SID Met+Cys requirements; Control), 2) Diet 1 + 0.28% MHA-Ca (MHA-Ca); and 3) Diet 1 + supplemented 0.18% DL-methionine (DL-methionine was supplemented at 65% of supplemented MHA-Ca in diet 2; 65 MetAMINO®).

Diets were formulated to meet or exceed NRC (2012) recommendations for all amino acids. Diets were corn-soybean-meal-whey based in phases 1 and 2 and corn-SBM based diets in phases 3 and 4. Diets were manufactured by a commercial feed mill.

Trial results

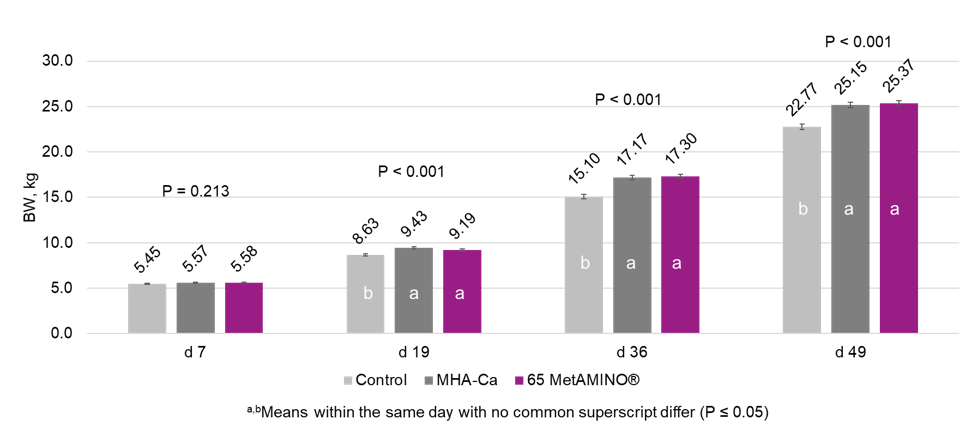

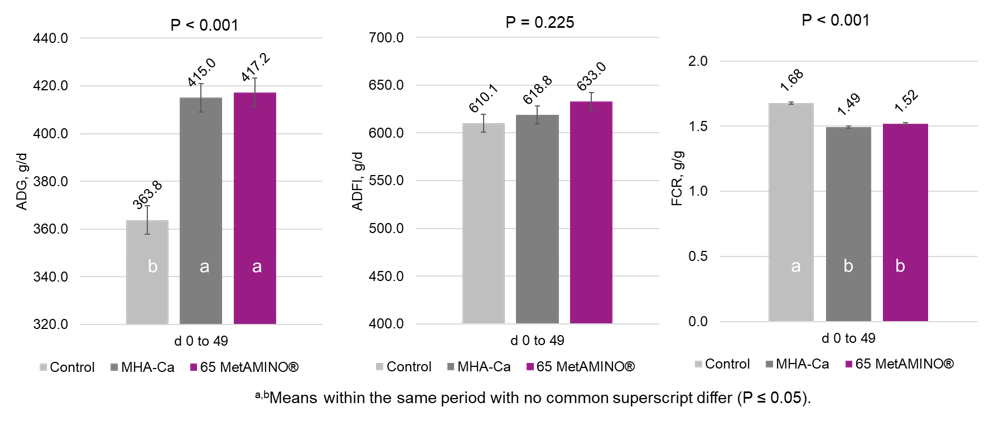

The nutrient analysis of the diets demonstrated that the achieved DL-methionine to MHA-Ca ratio was 66% for the overall study. As shown in Figure 1, no statistical difference was observed on body weight at the end of phase 1, 2, 3, and 4 between pigs fed 100 parts of MHA-Ca or 65 parts of DL-methionine. There was no difference in ADFI among treatments. Pigs fed 100 parts MHA-Ca and 65 parts DL-methionine did not differ in final ADG and FCR (Figure 2).

The results of this trial are also in agreement with Rademacher et al. (2004), Zimmermann et al. (2005), Santos et al. (2007) and Htoo and Morales (2012). For instance, Zimmermann et al. (2005) observed a lower performance for the control (methionine-deficient) group and no difference in ADG (488 vs. 501 kg/d) and FCR (1.48 vs. 1.48) between the growing pigs fed MHA-FA or 65 parts DL-methionine, respectively.

Economic savings with MetAMINO® (DL-methionine)

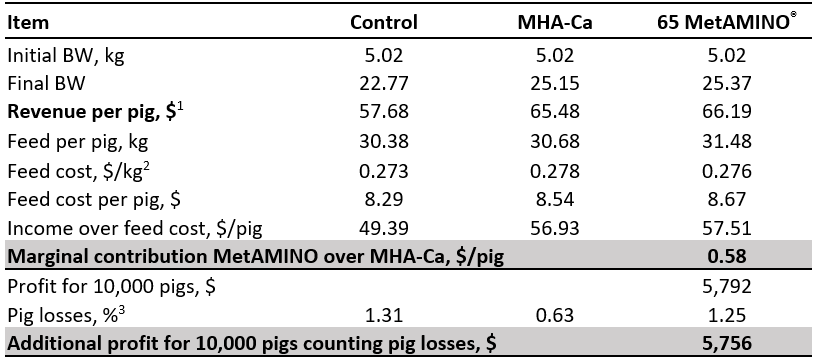

The economic evaluation, using the current trial results, indicates a higher income over feed cost (+ 0.58 US$/pig) by using MetAMINO® at 65 parts of MHA-Ca compared with using MHA-Ca (Table 1). To expand the profitability analysis for producing 10,000 nursery pigs and adjusting for the pig losses, an additional profit of US$ 5,756 can be achieved by using MetAMINO® at the dietary inclusion of 65 parts of MHA-Ca. Overall, the current trial results demonstrated that the 65 parts of DL-methionine can replace 100 parts of MHA-Ca and achieve the same pig performance and increase the profit of pig production operations.

1 Based on the Q1 2020 average price of 3.34 $/kg for feeder pigs of 5.4 kg BW and 3.27 $/kg for feeder pigs of 18.1 kg BW (USDA Feeder Pig Quarterly Report).

2 The feed price is a weighed price based on feed intake in each phase and the cost of feed of each phase. Cost of the control diet were 606.01, 460.73, 213.15, and 202.46 for phase 1, 2, 3, and 4, respectively. The cost of the MHA-Ca and MetAMINO® diets were estimated by the addition of the cost of the control diet plus the analyzed contented of MHA-Ca and MetAMINO® multiply by the price of the ingredient ($1.68 and $2.1 per kg of MHA-Ca and DLM, respectively).

3 Pig losses referred to pigs that were removed of the experiment or died.

Conclusion

The present US trial was designed to feed MHA-Ca to achieve 100% of the SID Met+Cys:Lys requirements. It was demonstrated that pigs can achieve the same performance with DL-methionine at 65% of MHA-Ca. Investigating the performance of the methionine sources at the SID Met+Cys:Lys level used in a swine operation has practical and relevant implications for generating savings.

| References | ||||

|---|---|---|---|---|

| Facts&Figures No. 1496: A | ||||

| Vietnamese study showed a lower bioavailability for methionine hydroxy analog calcium salt relative to MetAMINO® in starter pigs.. Evonik Trial No. | 03.63.11001. | |||

| Htoo, J. K. and J. Morales | ||||

| (2010) | Requirement of Lys and Met + Cys for 10 – 20 kg pigs with high lean growth potential.. 11. Tagung Schweine- und Geflügelernährung, Halle (Saale) | 23.-25. November, 65-67. | ||

| Kim, B. G., M. D. Lindemann, M. Rademacher, J. J. Brennan, and G. L. Cromwell | ||||

| (2006) | Efficacy of DL-methionine hydroxy analog free acid and DL-methionine as methionine sources for pigs.. J. Anim. Sci. | 84:104–111. | ||

| Malik, G., D. Hoehler, M. Rademacher, M. D. Drew, and A. G. Van Kessel | ||||

| (2009) | Apparent absorption of methionine and 2-hydroxy-4-methylthiobutanoic acid from gastrointestinal tract of conventional and gnotobiotic pigs.. Animal. | 3:1378-1386. | ||

| Rademacher, M., M. Lindemann and S. Illan | ||||

| (2004) | Effectiveness of liquid MHA-FA compared with DL-Methionine in piglets.. 8. Tagung Schweine- und Geflügelernährung, Halle, | 156-159. | ||

| Santos, O., A. G. Borbolla, A. Pineda, R. Flores, A. Pinelli-Saavedra, and D. Hoehler | ||||

| (2007) | Performance of pigs fed diets supplemented with DL-Methi- onine or liquid MHA-FA from 6 – 25 Kg.. ADSA-PSA-AMPA-ASAS Joint Annual Meeting, San Antonio, TX, | July 8-12, Abstract 625. | ||

| Zimmermann, B., R. Mosenthin, M. Rademacher, P. B. Lynch and E. Esteve-Garcia | ||||

| (2005) | Comparative studies on the relative efficacy of DL- methionine and liquid methionine hydroxy analogue in growing pigs. Asian-Austr.. J. Anim. Sci. | 18:1003-1010. |