Ambient Air Quality Regulations That Impact Swine Operations

Current air quality regulations, why they were implemented, what swine operations are affected and how to comply are explained by Erin Cortus of South Dakota State University and Richard Stowell of the University of Nebraska-Lincoln in a Factsheet for Pig Information Gateway.Introduction

Agricultural air quality is a hot topic around the United States. Increasing interest in air quality regulation of farms is the result of many changes, including the trend toward larger farms having greater concentrations of animals, and increased knowledge and awareness of air emissions from livestock sources.

This document provides background on current air quality regulations, why they were implemented, what swine operations are affected, and how to comply, when necessary. Indoor air quality will not be directly discussed here, but readers should understand that indoor air quality and outdoor air quality are related, and the level of indoor air quality is not necessarily indicative of emission levels.

In a regulatory context, ambient air is the outdoor air that surrounds our homes, farms and businesses. Maintaining good ambient air quality should be a concern for pork producers and others involved in agriculture because it is an inherent part of environmental stewardship. Specific reasons of importance to many pork producers include:

- Manure nutrients that are lost to the air (i.e. ammoniacal nitrogen) lower the nutrient value of manure as a fertiliser

- Some emissions may have far-reaching negative impacts when they are re-deposited downwind

- Air emissions can carry some swine disease organisms from one facility to another

- Odour and other air quality degradation (even the remote potential for it) can create tension among neighbours

- Degraded air quality leads to new and stricter regulations.

Background on Air Quality and Regulations

Pork operations or facilities generally produce airborne particulate matter (e.g. dust, or other solid or liquid material suspended in the air) and several gases (i.e. ammonia, hydrogen sulphide, carbon dioxide, methane and nitrous oxide) that are addressed in current federal ambient air quality rules and regulations1.

Odoor is not regulated by the federal government. Odoor considerations may, however, exist at the state or county level. When it comes to air quality regulation, it is important to understand the difference between concentration and emission and the relationship between the two.

Concentration is the quantity of something (odour, dust, gas, etc.) in a given amount of air; commonly stated as parts per million (ppm) or per billion (ppb), or as fractions of a gram per cubic meter of air (e.g. µg/m3 ).

Concentration measurements are used to assess the quality of the air, and are often used to evaluate the effectiveness of control measures and regulations. If ambient air concentrations exceed established air quality standards (described in the Clean Air Act section), an area may be placed in ‘non attainment status’ and stricter requirements may be enforced within that area.

The Environmental Protection Agency (EPA) maintains a list of non-attainment areas in their ‘Green Book’ (available online, see For Further Information). Emissions are generally expressed as rates, where the emission rate is the amount of something (odour, dust, gas, etc.) that moves from a defined source (building, storage area, surface, etc.) or set of sources into the ambient air during a measured period of time.

For example, the amount of gas leaving a barn and moving into the surrounding air over a period of time establishes an emission rate (i.e. lb per day, grams per hour). When air moves across the surface of an open manure storage facility or treatment lagoon, it picks up gases, resulting in another source of emissions. To calculate an emission rate, pollutant concentrations at the source and of the ambient air must be known.

If you think of a smokestack, in order to know how much of something, e.g. hydrogen sulphide, is coming from this source, we need to know first how much air is moving through the stack, and then, how much hydrogen sulfide is in that air. In other words, we need to know the airflow rate and the net pollutant concentration.

The same principles apply for emissions from animal facilities. An important thing to keep in mind is that airflow rate and pollutant concentration are often inversely related. For example, in warmer weather, pollutant production within the facility may increase but the ventilation also increases and so the pollutant concentration in the animal area is generally reduced.

In reality, emission rates are often lowest when indoor pollutant concentrations are highest (in cold weather) and vice versa.

Most air quality regulations are designed to regulate emissions from the source, with the intent being to favourably influence ambient air quality – as assessed by off-site pollutant concentrations.

Clean Air Act (CAA)

Background

The Clean Air Act establishes public health-based standards called NAAQS (National Ambient Air Quality Standards). NAAQS have been established for six ‘criteria pollutants’: particulate matter (PM), ozone, carbon monoxide, sulphur oxides, nitrogen oxides and lead. Of these, only particulate matter is typically generated by livestock production. The main public health concern with particulate matter (PM) involves ‘fine particulates’ (PM2.5), which, because of their very small size, have been shown to get deep into human lungs and contribute to respiratory illness.

EPA currently regulates both fine and ‘coarse inhalable particles’ (PM10) via NAAQS, although there is movement toward regulating mainly or only PM2.5. Ammonia has been shown to react with other air pollutants in the atmosphere to form PM2.5, leading to concerns about future regulation of ammonia emissions under the Clean Air Act.

States are responsible for establishing procedures to attain and maintain the NAAQS via ‘state implementation plans’ (SIP). The SIP procedures that must be taken and the requirements placed upon PM sources depend upon whether an area is designated by EPA to be in attainment or nonattainment of the NAAQS. An interactive map showing the status of SIP requirements for designated areas within each state is available online (see Further Information). EPA may enforce the NAAQS by requiring:

- Air permits for major sources of criteria pollutants and other hazardous air pollutants

- Implementation of control technologies EPA is also required to establish standards for ‘hazardous air pollutants’ (HAP). These substances are known or suspected causes of human health ailments, including cancer.

EPA has identified categories of industries that have the potential to produce these substances. Livestock and poultry operations are not currently included in this list of categories. None of the main gases generated within swine facilities (ammonia, carbon dioxide, hydrogen suphide, methane) is currently considered hazardous air pollutants in the context of having to meet HAP standards.

While the current list of about 190 HAP does include hydrogen sulphide, a note identifies this as being erroneously listed for this purpose.

What farms may be affected

The vast majority of swine operations are not currently affected by Clean Air Act regulations.

Particulate matter (PM10) is the most prevalent of the currently regulated pollutants emitted by animal feeding operations. On the one hand, raising pigs does generate dust, and confinement buildings may have elevated concentrations of coarse and fine particulates (PM10 and PM2.5), especially when operating at minimum ventilation rates, that do warrant consideration of indoor air quality. Particulate emissions from swine facilities are relatively low compared to many industrial operations.

Recent emission monitoring studies suggest that swine operations generally do not exceed particulate matter emission thresholds within attainment areas. Designations (as of July 2014) for PM10 and PM2.5 show major pig-producing areas in the US to be in attainment of the NAAQS. The major source threshold in attainment areas is 100 tons of PM10 per year, and direct emissions from swine facilities are projected to be below 100 tons per year.

The odd scenario that may get regulatory attention might be a large swine operation within a non-attainment area. Farm operations that look to install large stationary engines – like those used to generate electricity from digester biogas – may need to assess the expected nitrogen oxide (NOx) exhaust emissions, especially if the site is located in a non-attainment area, since nitrogen oxide is a regulated criteria pollutant.

Pork producers should be attentive to regulatory discussions about ammonia emissions and ‘reactive nitrogen’, since ammonia emissions from pig production and manure handling facilities can be substantial. There is growing agricultural concern that EPA will seek to regulate emissions of ammonia and farm derived volatile organic compounds (VOC) under the Clean Air Act due to their effects as secondary compounds. Since ensiled feeds – the main farm source of VOC – are not significant components of pig rations, VOC regulations are less of a concern for pork producers.

How to comply

If in the uncommon situation where you may need to comply, work with a qualified consultant and your state agency in charge of the State Implementation Plan.

Bottom line

Clean Air Act regulations are unlikely to impact swine operations that are not in a non-attainment area but large operations should stay informed on the direction of EPA policy in interpreting and enforcing the Clean Air Act.

Emergency Planning and Community Right to Know Act (EPCRA)

Background

EPCRA is designed to help federal, state and local governments, Indian tribes and industry in emergency planning, emergency release notification, hazardous chemical storage reporting, and toxic chemical release inventory2. Essentially, it creates a public list of where hazards are located in a community so that emergency personnel and others are aware and can act accordingly.

A related regulation, the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) is implemented by EPA to facilitate remediating hazards via ‘Superfund’ projects. For many years, it was commonly assumed that EPCRA and CERCLA did not pertain to the normal emissions associated with agricultural practices, but pressures grew that questioned this assumption.

In 2009, EPA implemented a ruling3 that exempted all animal feeding operations from reporting ‘releases’ of normal agricultural emissions under CERCLA. The same rule also exempted ‘small and medium animal feeding operations’ from reporting these emissions under EPCRA.

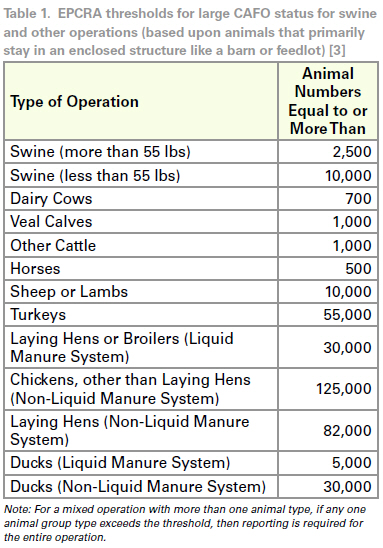

The main impact of this ruling was that it became clear that larger confinement facilities that meet EPA’s ‘large CAFO’ status (see Table 1) need to report emissions of individual hazardous pollutants exceeding specified limits (typical threshold is 100lb per day). The list of hazardous pollutants to report includes ammonia and hydrogen sulphide, which are both common manure-based gases. Ammonia releases are typically greater than hydrogen sulphide, with ammonia being the dominant form of nitrogen loss on farms.

What farms may be affected

If a facility is a large CAFO according to EPA, and has the reasonable potential to emit more than 100 lb per day of either ammonia or hydrogen sulphide, the facility is required to submit a report under EPCRA according to the 2008 final rule.

Two main factors that increase the likelihood that an operation needs to report emissions include size of the facility (more animals more manure more manure gas emissions) and lack of control over nitrogen loss prior to application of manure (more nitrogen lost more ammonia emissions). To see if your operation will be affected, first determine if you are exempt based upon the total one-time pig capacity of your facility.

EPA uses language that is used with NPDES permits to determine what animals must be included and what defines a ‘facility’ for EPCRA reporting. For a single-phase production facility, is the capacity equal to or greater than the number in Table 1 – e.g. is there one-time capacity for raising 2,500 or more pigs at a grow-finish site?

For a facility having multiple phases, like a farrow-to finish facility, refer back to your operation’s CAFO status based upon the number of animal units. If your facility is not a large CAFO, it is exempt from EPCRA reporting. For clarification of untypical scenarios, work with a qualified consultant and your state environmental agency. Swine operations tend to come in certain sizes, with increments of 1,000 or 1,200 head being most common for new facilities.

A stand-alone facility with 2,000-head or 2,400-head of large pig capacity fairly common sizes for sow and finishing buildings would not be considered a large CAFO and does not need to report normal air emissions under EPCRA. A comprehensive assessment of emissions studies on swine farms4 reports that, using median (half above, half below) emission rates, the threshold would not be exceeded at 3,400 hogs.

Emissions measurements show a lot of variability, though, and Liu and Powers4 stated that a 3,000-head swine facility has a 25 per cent chance of emitting more than 195lb of ammonia a day, which is almost twice the reporting threshold. The average emission results from the National Air Emissions Monitoring Study (NAEMS) – an extensive field study conducted to help establish regulatory thresholds for reporting - indicate the threshold is exceeded well below 2,500 head.

So, while not all large-CAFO swine facilities may actually emit more than 100lb a day of ammonia, they are all affected in terms of doing some sort of evaluation and risk assessment to either report or justify not needing to report under EPCRA.

How to comply

If the facility is a large CAFO, the first step toward compliance is to estimate peak 24-hour ammonia and/or hydrogen sulphide emissions from your facility.

Determining daily farm emissions of ammonia and hydrogen sulfide remains a major challenge. EPA’s pursuit of using the results of the National Air Emissions Monitoring Study to determine an operation’s emissions for regulatory purposes has been slowed as it addresses several questions and criticisms. Current reporting is done based upon ‘good faith’ estimates from applicable field studies or projections based upon nutrient balances. Several calculators are available to help estimate ammonia emissions.

If the applicable emissions estimate for your facility exceeds the 100lb per day threshold, you will need to contact your state agency in charge of emergency response and submit a report. EPA provides basic info on what is required, but how reporting is done varies by state. General guidance is to work with a qualified consultant or advisor to arrive at applicable emissions estimates, assemble documentation needed to report or justify not reporting, and perform required reporting steps.

No further reporting is required unless there is an increase in facility capacity or a change that would substantially affect the rate of emissions. EPCRA reports are kept on file by state and local authorities and are public record.

Bottom Line

Large operations should assess their need to report under EPCRA based upon animal capacity and potential ammonia emissions.

Greenhouse Gas (GHG) Reporting Rule

Background

In 2009, the GHG Reporting Rule was implemented by EPA to provide a better understanding of where greenhouse gases are coming from so that, in the future, policies and programs can be implemented to effectively reduce emissions5,6. Greenhouse gases (GHG) include carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, and sulphur hexafluoride. Any facility that emits more than 25,000 metric tons of ‘carbon dioxide equivalent’ is required to submit annual reports documenting measured or estimated emissions.

‘Carbon dioxide equivalent’ is a method of reporting the impact of multiple greenhouse gases with varying degrees of global warming potential as though the total warming potential came from carbon dioxide.

The GHG Reporting Rule only addresses one component of livestock GHG emissions – manure management5. In the agriculture sector, cattle and other ruminants naturally produce methane and carbon dioxide as part of their digestive and respiratory processes.

Non-ruminants, like swine, also produce carbon dioxide but methane production is considerably lower. The GHG Reporting Rule does not require reporting of methane and carbon dioxide that are directly emitted by animals. Manure management, however, and the methane and nitrous oxide that are produced by biological manure processes, are included in the GHG Reporting Rule (Subpart JJ). The following types of manure management systems on swine operations are included in this category:

- uncovered anaerobic lagoons

- liquid/slurry systems (with and without crust covers)

- storage pits

- digesters, including covered anaerobic lagoons

- solid manure storage

- deep bedding systems, and

- manure composting, aerobic treatment.

What farms may be affected

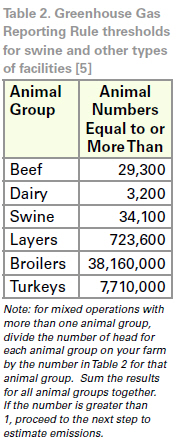

Only very large facilities are required to report greenhouse gas emissions. EPA estimated that only 107 livestock facilities nationwide would produce the 25,000 metric tons of carbon dioxide equivalent from manure management sources1 and the projected threshold facility sizes are shown in Table 2 for single-species operations.

If the average annual animal population is (and remains) less than that presented in Table 2 for a given animal facility – for swine, the threshold is 34,100 pigs – there is no need to report GHG emissions.

How to comply

Soon after the GHG Reporting Rule was published, Congressional Appropriations Committee actions prohibited EPA from expending funds to implement Section JJ of the reporting rule, and this restriction remains in effect as of federal fiscal year 2013-14. Affected livestock producers are left in the precarious position of officially being required to report GHG emissions without being able to obtain additional guidance from EPA or certainty that EPA will actually ever require the reports.

While no enforcement of the reporting rule for livestock operations is currently allowed, there are producers who are reporting emissions to minimise their non-compliance risk. All affected producers are advised to maintain sufficient inventory and operational records to facilitate future compliance, should the restriction on implementation of the rule for manure management be lifted.

For facilities having animal numbers above the exemption threshold, reporting is only required if annual emissions of greenhouse gases (primarily methane) resulting from manure storage and handling are equivalent to 25,000 metric tons of carbon dioxide. EPA provides specific guidance in the rule for estimating reportable GHG emissions, assessing the need to report, and annual reporting requirements. The estimates are made using a series of calculations and look-up values that are based upon the animal type and region. Use of a qualified consultant is advised.

Bottom line

Reporting is only required of very large farms, and implementation of the rule for livestock operations is in limbo due to congressional budgetary restrictions placed upon EPA.

State and Local Regulations

Background

State environmental regulations include SIP for implementing federal regulations and rules that address other state air quality concerns. Many states require animal feeding operations seeking a construction permit to develop a plan to control odor and/or air quality concerns.

Some states, e.g. Minnesota and Nebraska, have regulations related to off-site hydrogen sulphide and/or particulate matter concentration that apply to livestock operations. Several states, e.g. Missouri and Colorado, have rules that limit off-site odour concentration. Some states, e.g. Minnesota, Nebraska, South Dakota, give counties and other local governing bodies authority to develop and enforce regulations that relate to air quality, while others do not or limit what can be enforced to what is in state policy.

In states allowing ‘local control’ of livestock operations, the regulation generally occurs in the form of setback distances. A set-back distance is the distance between the emission source and a specific site (e.g. school, township road, neighbouring residence). Less frequently, specific control measures (e.g. cover on manure storage, biofilter on pit fans) may be required.

What farms may be affected

Regulatory impact depends on the location and the specific rules that apply within the area. Expanding operations are typically most affected by state and local regulations. In states having rules limiting offsite hydrogen sulphide concentrations, there usually is an allowance for a specified number of ‘exceedances’ that accounts for the need to agitate stored manure prior to application.

This greatly reduces the number of affected operations, generally to those that store relatively large quantities of manure and have ongoing air quality issues. State and local odour rules vary in scope and application. In some cases, it is difficult to determine who might be affected even when the rules are clearly stated.

In general, odour rules are more likely to be enforced for operations that are: considered large for the area, near a residential area or have vocal ‘concerned neighbours’, and/or not using generally accepted best management practices (especially for manure handling and application).

How to comply

Determine what state or local air quality rules are in place that apply to your operation. Expanding swine operations need to integrate state air quality rules and local zoning ordinances into facility planning. Work with a qualified consultant or Extension Specialist and contact your state environmental agency or county commission if you have questions about regulations for swine facilities.

Summary

Federal air quality regulations exist to protect the general public and the environment from detrimental impacts of air pollutants. These regulations were often developed with industrial operations in mind, but can apply to agricultural operations. Swine facilities that are designated by EPA as meeting or exceeding large CAFO status bear the brunt of current federal air quality regulations, which mainly consists of reporting requirements for ammonia under EPCRA and possibly greenhouse gas emissions for very large operations.

The responsibility and decision to comply rest with individual producers. As these are federal regulations, with both known and unknown consequences for compliance, operators may want to discuss with legal counsel. More pork producers are likely to be affected by state regulations and local requirements than by federal air quality regulations.

Producers who are planning to expand their operations, and those with facilities of any scale that have significant potential for neighbor conflicts, are most likely to be affected. Regulatory policies vary from state to state and local rules can vary widely within states that facilitate ‘local control’. Producers need to refer to governing requirements that apply for their specific locations and should get assistance as needed from a qualified consultant.

Further Information

Research is ongoing to evaluate the effects of different livestock production practices and mitigation technologies on air emission rates, as well as to assess potential regulatory ramifications. In the meantime, local Extension personnel can address your questions and can offer guidance in making calculations or estimations for your operation.

Further information can also be found at:

- Environmental Regulation and Agriculture. Farmpolicy.com

- Manure Management Systems. Final Rule: Mandatory Reporting of Greenhouse Gases. EPA.

- CERCLA/EPCRA Administrative Reporting Exemption for Air Releases of Hazardous Substances from Animal Waste at Farms EPA.

- Livestock and Poultry Environmental Learning Center – Regulations Related to Livestock and Poultry Production Extension.org

- Environmental Protection Agency – The Green Book Nonattainment Areas for Criteria Pollutants

- Environmental Protection Agency – Status of SIP Requirements for Designated Areas

References

- CRS. Environmental regulation and agriculture. 2011. Congressional Research Service Report R41622.

- EPA. The Emergency Planning and Community Right-to-Know Act. 2000. United States Environmental Protection Agency, Office of Solid Waste and Emergency Response. Factsheet EPA-550-F-00-004.

- EPA. CERCLA/EPCRA Administrative Reporting Exemption for Air Releases of Hazardous Substances from Animal Waste at Farms. Federal Register. 2009; 73(244):76948–76960.

- Liu Z. and Powers W. 2013. Emissions of NH3, H2S, VOC, PM10 and PM2.5 from swine production facilities in North America: a meta-analysis. ASABE, St. Joseph, MI. Paper No. 131594405.

- EPA. Manure Management Systems. Final Rule: Mandatory Reporting of Greenhouse Gases. 2009. United States Environmental Protection Agency. Factsheet EPA-430-F-09-026R.

- EPA. Mandatory Reporting of Greenhouse Gases. Federal Register. 2009. 74(209):56337 and 56481.

November 2014