Back to the Basics of Feeding Pigs

Reliable nutritional information, whether from book values or laboratory analysis, is important to determine what diet will meet a pigs’ requirements to grow, reproduce, produce milk, fatten or maintain its weight depending on stage of life, writes Anita Heeg, Feed Ingredients and By Products Specialist, in Pork News and Views.This information can be obtained from a laboratory feed analysis. Many producers use book values instead of getting a laboratory analysis. When comparing these, laboratory values are more accurate, representing the actual values of each nutrient. For example, lysine levels are often estimated by analyzing for crude protein.

Both wet chemistry and near infrared spectroscopy (NIRS) are methods commonly used to obtain parameter values. Wet chemistry measures the nutritional value by drying the ingredient, followed by the use of heat and chemicals. For example, Neutral Detergent Fiber (NDF) is the fiber portion that is not broken down when boiled in a neutral pH solution.

NIRS estimates the nutritional value of the feed using light reflection rather than chemistry to identify and measure amounts of compounds in a sample. The reflectance values are entered into calibration equations, which estimate nutrient values based on a large database determined by wet chemistry.

This method is commonly used for obtaining crude protein, moisture, crude fiber, ash and fat. This provides fast, reproducible and cost- effective results with minimal sample preparation by the laboratory.

Each laboratory will have a set of packages available to obtain various parameters based on the customer’s needs. Of course the analysis is only as good as the sample submitted to the laboratory. A good sample should be representative of the entire feedstuff sent in for testing. To do so, grab samples from multiple spots and mix them to create a composite sample, and then obtain a sub sample for the testing.

The following are explanations of the terms found on a laboratory report.

Dry Matter

Each feed analysis report specifies the dry matter and moisture of the feed analyzed. The dry matter is the moisture free material left after drying the sample. Moisture dilutes the concentrations of the nutrients present, and it is standard practice to evaluate the feed and balance rations using a dry matter basis. High moisture ingredients may not just affect the concentration of nutrients, it also creates a difficulty when incorporating the ingredient into a practical feeding program. Nutrients present can be classified into five main groups; energy, protein, minerals and vitamins, with the fifth one being water.

Protein

Crude protein (CP) is calculated and based on the nitrogen content of the feedstuff. The soluble portion of crude protein is most readily available to animals. This consists of small amino acid chains, or non-protein-nitrogen. Protein is made up of approximately 16% nitrogen and, in the lab, total nitrogen is measured and multiplied by 6.25 (100/16) to report it on a “crude protein” basis. Without looking at the type of protein CP is made up of, it gives no information on the amino acid content or its availability. It plainly indicates that it contains nitrogen, including both true protein that contains amino acids (the building blocks of protein) and non-protein-nitrogen (NPN). NPN includes urea and ammonia that contain nitrogen.

There are 10 amino acids categorized as ‘essential amino acids’ which the animal cannot synthesize, or not at a rate to meet the animal’s needs. They are Phenylalanine, Valine, Threonine, Tryptophan, Isoleucine, Methionine, Histidine, Arginine, Lysine and Leucine. Since lysine is the most limiting amino acid for pigs, it is used to formulate a diet allowing some amino acids to be in excess. The remainder of the amino acids requirements are expressed as a ratio to lysine and added via protein or synthetic sources. Non-essential amino acids can be synthesized by the animal since they have the ability to convert surplus amounts of one amino acid to another to meet its needs through complex processes completed by enzymes. Nevertheless, both essential and non-essential amino acids are needed for the animal to thrive.

Energy

Energy is obtained from lipids (fats and oils), protein, and carbohydrates such as starch, sugar and fiber. The two primary sources of energy in swine diets are carbohydrates and lipids. Energy from protein is utilized when protein is in excess to the animal’s requirements. However, excessive amounts of protein not utilized to its full potential are expensive, may affect feed efficiency and creates excess nitrogen which is excreted into the environment.

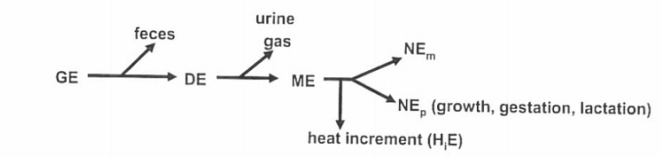

Energy is calculated and reported as gross energy (GE), digestible energy (DE), metabolizable energy (ME) or net energy (NE) and are very important contributors to the diet to reduce cost while maximizing pig performance. As shown by the NRC in Figure 1, the gross energy refers to the total energy available in a feed. This is then fragmented into DE where the energy of faeces is removed, followed by ME, where the energy for urine and combustible gases is subtracted off of DE to obtain ME. NE accounts for the thermal losses and can be divided according to its utilization; maintenance (NEm) or production (NEp), which includes growth, gestation and lactation. NE is mostly used by nutritionists as it’s ingredient dependent; being lower for protein and fiber, but higher for fats and starches. However, DE is probably most likely to be understood and used by producers. If highly digestible ingredients are used, the values for DE and ME will be more accurate. Adding by-products high in fiber to the mix will affect the DE and ME values to some extent due to energy and heat present through internal interactions, making NE a more reliable value. In addition, studies suggest that by using NE values, feed cost and nitrogen excretion can be reduced.

Fats/Lipids/Oils

Fats such as oils and lipids are added to manage energy levels of the diet and vary in digestibility depending on chain length and saturation. Saturated fats are made of single carbon bonds only. The digestibility is affected by the ratio of unsaturated to saturated fatty acids and declines as the ratio falls below 1.6 to 1. In addition, as the length of the chain increases, the digestibility decreases.

Price and digestibility are the main factors affecting the determination for ingredients to be used as a fat source. Fats are highly palatable and can be added during extreme heat to provide energy while producing little additional body heat due to digestion. The type of fat can affect the quality of the carcass; feeding high amounts of saturated fats produces high saturated fats in the pigs’ body fat and is regularly added to finishing diets for that purpose. Fats added to diets can improve palatability and is also a means to control dust in feed, while acting as a lubricant during the manufacturing of feeds, especially pelleting. However, fats added in excess quantities can decrease pellet quality, impact animal performance and feed efficiency. Fats have more impact on the latter during hot summers than during colder seasons. This is important because if feed intake goes down, the concentration of other nutrients required need to be increased to meet the pigs’ demands. The ratio between calories and amino acids consumed must be kept consistent.

For example: A swine diet consists of 3400kcal/kg DE with 0.85% lysine. A pig eats 1.6kgs/day of this diet, consumes 5440kcal and 13.6g of lysine a day. Heat stress sets in and we increase the energy content of the diet to 3600kcal/kg DE. Assuming the pig still eats the 5440 kcal a day as it adjusts to meet energy requirements, the pig will now eat 1.51kgs/day and was unable to maintain its lysine intake which decreased to 12.8g/day. Therefore, for this particular diet the lysine concentration will need to be increased to 0.9%.

Carbohydrates

Carbohydrates play an important role in providing energy to the animal and are made up of chains of sugars linked together and are named according to the number of single sugars bonds: monosaccharides, disaccharides, and polysaccharides. Similar to protein digestion, enzymes are needed to break down the carbohydrates to make them available. However, monogastrics lack the enzymes to break down complex sugars found in legumes as well as those found in soybeans. For this reason enzymes are often added to the diet.

Starch/Sugar/Fiber

As said before, simple sugars and starches are used as a source of energy for pigs. Simple sugars such as glucose and lactose are great for energy sources for young pigs, but caution is advised when feeding fructose and sucrose as it may cause diarrhea. Due to its costs, sugars are most often used in neonates. Starches are the main energy source, but are not well digested by pigs until they are 3 weeks old.

Fiber is another energy component and is referred to as acid detergent fiber (ADF) and neutral detergent fiber (NDF) and is determined by laboratory testing. Although some nutritionists see these components more applicable to determining a ration for ruminants, it gives an indication of the digestibility and energy available. ADF to refers to the cell wall portion and is made up of lignin and cellulose. The value is important as it relates to the ability of an animal to digest where a higher ADF suggests a decrease in digestibility. NDF refers to the cell wall fraction that includes lignin, cellulose and hemicellulose. Looking at both the ADF and NDF, nutritionists are able to determine the digestibility and energy available to the animal.

Minerals

Minerals are added when the basal diet provides insufficient quantities. Minerals are categorized between macro minerals (calcium, phosphorous, sodium, chloride, potassium, magnesium) and micro minerals (iron, zinc, copper, manganese, iodine, and selenium). Macro minerals such as calcium, phosphorous, sodium, and chloride make up the majority of the required minerals.

Phosphorous (P) levels, however, create a concern for the environment and ingredients are evaluated to have a high P digestibility to avoid over feeding and match the animals’ needs.

Additional phytase is added to aid its digestion, as P is involved in essential metabolic processes. Calcium plays an important role in bone mineralization and is usually expressed as a ratio to total P- typically at a ratio of 1.0 to 1.5, or as a ratio to available P of 2.1 to 3.1.

Vitamins

Vitamins are essential in generating chemical reactions needed for metabolism and almost all are made up of carbon, oxygen and hydrogen. Vitamins are needed in much smaller amounts than any other ingredient, yet there can be adverse effects when animals are deficient. There are two types of vitamins, water soluble and fat soluble. Water soluble vitamins cannot be stored in the pigs’ body, and excess is excreted mainly in urine. Water soluble vitamins include vitamin C, thiamin, riboflavin, niacin, vitamin B6 and B12, folate, biotin, choline, and phanthothenic acid. Vitamins A, D, E and K are considered fat soluble and are important for the animal to function and maintain health. Vitamins A and E may be added to the diet separately or incorporated into the minerals as a supplement. This gives the feed manufacturer flexibility in preparing diets based on the stage of life the diet is being manufactured for. Due to their low inclusion rate, these are a small price for the benefits vitamins provide.

Water

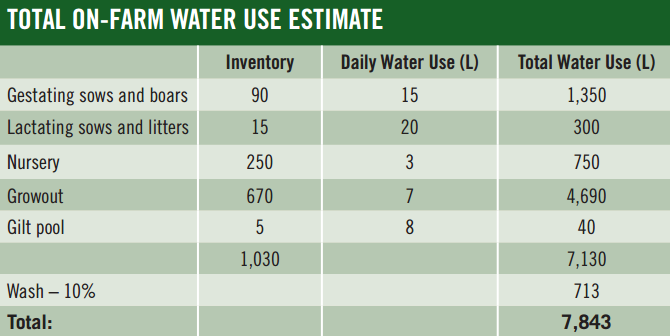

In addition to the nutritional analysis of feed, water testing should also be done regularly. Water is often the forgotten nutrient yet is so important. Remember that water makes up 70% of the live weight and body water turnover is higher in young and highly productive animals, especially during lactation. Table 1 shows the water intake of sows, farrow to finish, (Pork Production Reference Guide 2000, Prairie Swine Centre Inc). Water quality must be tested routinely and be free of high concentrations of adverse minerals, sulphates, bacteria contamination, and chemical contamination.

Remember that nutrient recommendations are guidelines containing a safety margin to account for the variation found in ingredients used. Laboratory analyses of ingredients help to create a cost effective and balanced diet while meeting the animals’ requirements. In addition, good quality water should be provided, as it is required in greater quantity than any other nutrient.

amount of spill from drinkers, the extent of washing and system leakage. Water usage has been reported

as low as 65L/sows and as high as 120L/sow. Clearly, more-research is required in this importan anrea.

Table 1: Water use estimates in pork production (PSC).