Indoor housing systems for dry sows

Compassion in World Farming discusses indoor group housing systems for dry sows and provides an up-to-date comparison of how such systems meet the needs of the sow and the stockworker

Individual stall housing for dry sows beyond a period of four weeks after service is no longer permissible in any EU Member State (as of January 2013). Producers need either to convert existing housing or construct new housing to comply with the legislation. It is imperative they invest in systems that deliver good standards of welfare for their sows and respect all elements of the legislation affecting dry sow housing.

Compassion recommends

A good dry sow housing system should provide an interesting environment which allows for the expression of a wide range of behaviours. Feed and fibre provision should reduce aggressive behaviour, particularly around feeding, and allow for satiety. Aggression and the number of stressors during mixing of unfamiliar animals should be minimised. Attention should be paid to:

Non-aggressive behavioural expression, by providing

- material for rooting and foraging (example straw, rice husks, woodchip bark);

- a space allowance of 3m2 per sow or more;

- functional areas in the pen (example separate feeding, resting and activity areas).

Improving satiety, by providing

- fibre in the diet (example maize silage);

- a feeding method that minimises aggression and maximises duration of foraging.

Minimising aggression during mixing, by providing

- a specialised mixing pen with additional space per sow to allow subordinate sows to escape more aggressive sows;

- gradual familiarisation of sows via fence line contact;

- flexible barriers or large straw bales to escape behind;

- feed ad libitum for the mixing duration until sows have settled their social order.

.jpg) Since a range of systems are adopted by producers, this report considers the factors that affect the welfare of sows in group housed systems, describes the main group housing and feeding systems in commercial use and how they perform in relation to the needs of the sow, and suggests ways of assessing the welfare of sows in group housed systems. Only systems capable of complying with the legislation fully are considered.

Since a range of systems are adopted by producers, this report considers the factors that affect the welfare of sows in group housed systems, describes the main group housing and feeding systems in commercial use and how they perform in relation to the needs of the sow, and suggests ways of assessing the welfare of sows in group housed systems. Only systems capable of complying with the legislation fully are considered.

* Unobstructed floor area must be increased by 10% for groups of fewer than 6 animals and can be decreased by 10% for groups of 40 or more animals.

Key features of group housing

Space

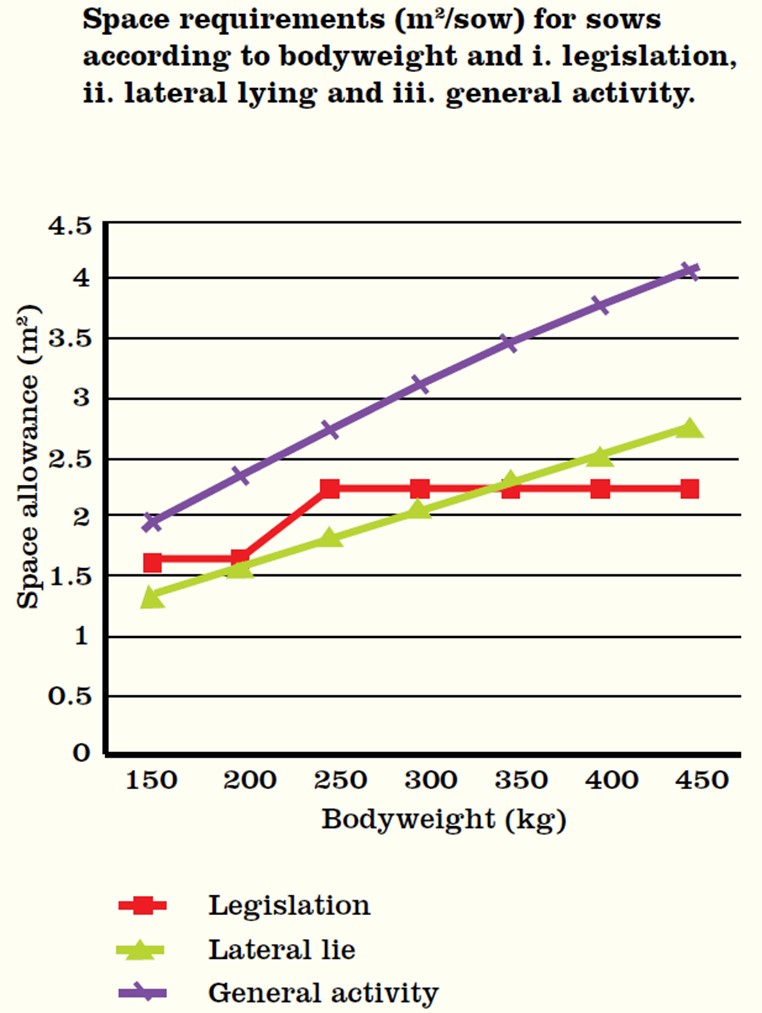

Insufficient space in group housed sows can increase the level of aggressive behaviour, particularly during feeding and mixing. This can lead to high rates of skin lesions, physical injuries and greater variation in condition throughout the group. Detailed requirements for space allowance according to body weight are obtained from recognised allometric equations which estimate the space required for lateral lying and general activity.

The space required for a sow to lie in lateral recumbency is given by the allometric equation A=kW0.67 where A is space in m2/animal, k is an empirical constant set at 0.0457 for lateral lying, and W is bodyweight. Extrapolation of the k value for general activity (of an animal in straw based systems with natural light) estimates k at 0.068.

This approach suggests the space required by law is low in terms of providing space for general activity, whilst experimental evidence suggests increasing space allowance above 2.25m2 per sow can have beneficial effects in reducing aggression and injury. Although further work on social space requirements is required, a more generous space allowance, closer to 3m2 per sow is advisable, and fits with the estimated value required for a group of average weight 300kg (see general activity line in graph opposite). Pen layout and sufficient space should allow sows to develop functional areas in the pen, for resting, feeding, drinking, rooting, and social interaction, whilst limiting aggression.

Flooring/bedding

Solid flooring, with good quality straw bedding which is changed regularly to maintain good hygienic conditions, has a positive impact on thermal comfort, hoof condition, lameness and skin lesions in sows. Straw bedding also has benefits in terms of providing gut fill and allowing for foraging behaviour. Additional substrates, such as woodchip bark, allow for other oral behaviours and may be appropriate in warm climates where the priority is to keep the sows cool. Foot lesions and lameness are prevalent in sows, and higher levels are associated with slatted flooring and lack of bedding. All flooring should be non-slip, clean and dry.

Solid floors with quality bedding increase comfort, foraging behaviour and physical health, and help provide satiation.

Fibre and foraging

In practice, conventional feeding systems provide pregnant sows with a concentrated diet aimed at maintaining condition without excessively increasing body fat. This is usually provided in one meal of 2-3kg per day, which can be eaten in 10-20 minutes. Although the Directive does not indicate levels of bulk or fibre in the diet, there is clearly a discrepancy between what legislation requires (the provision of enough bulky and high fibre diet to prevent hunger) and commercial practice. Straw-based systems provide some opportunity for increasing gut fill and foraging behaviour, whilst conventional feed delivery systems are not designed to deliver large quantities of bulky food. Research shows that providing silage on the floor, in a trough or in a rack on the wall, increases satiety and resting behaviour and can reduce aggression around feeding.

Managing aggression

Social interaction, including aggression, can occur in any group-housing system for sows, especially during mixing. High levels of aggression can result in injury, lameness, stress and return to oestrus. Space allowance, pen layout and feed delivery system are key factors affecting aggression. Group size may be less important, as successful systems can operate with a wide variety of group sizes falling into three main categories: small stable groups of approximately 4-6 sows which stay together until farrowing, large dynamic groups of 100 or more in which small groups of sows are removed and

added on a regular basis, and groups built up over a period of 2-3 weeks to a group size of 30-50 which remains stable until farrowing. Group size is related to housing/feeding system.

.jpg)

Fighting for social dominance in a newly-formed group is a temporary activity and more space should be provided to allow sows to move away from each other – a minimum space allowance of 3.5m2 per sow is recommended during mixing. As this is probably too high to provide in many systems on a permanent basis, there is a good argument for providing a specialised mixing pen with high space allowance which allows less dominant sows a reasonable flight distance, and physical barriers such as hanging colliery belting or big bales to escape behind.

All sows should have easy access to food, water and a lying area, and the use of ad-lib feeding for the short period spent in the mixing pen (a few days) should be considered. Group formation usually takes place at weaning or shortly after service, to avoid stress during the vulnerable implantation period during weeks two to three of pregnancy. Early mixing, if conducted well, does not impact on reproductive performance.

Once the avoidance order has been formed in the group, sows can be moved to a smaller pen for the remainder of pregnancy. In the case of small groups being moved into a large dynamic group, for example in an ESF system, they are likely to integrate with less aggression when introduced as an established group from the mixing pen. If possible there should be some physical contact (for example via a gate) between the sub group and main dynamic group before addition. Gilts should have a separate group, and be introduced to the main dynamic group during second pregnancy. For a suggested layout for a mixing pen, read the full report.

The main group housing and feeding systems in commercial use

Floor feeding... This involves delivering feed to groups of sows on a bedded lying area, and is suitable for a wide variety of building types and group sizes. Feed can be delivered by hand, or from a series of containers suspended above the lying area which are connected to a bulk bin via an auger. Food can be dropped directly from the containers (dump feeding) or thrown over a wider area (spin feeding). Mechanical feeding can be automated so that the stockperson does not have to be present, although this is the ideal time to observe sow condition and levels of aggression. Regular calibration of equipment is essential to ensure even feed supply.

Lockable feed stalls... These are full length stalls which are locked by the stockperson, or by the sow via an up-and-over back gate. They can be incorporated into a system with a separate straw-bedded lying area (which may have a roof) and a dunging area between the feed stalls and kennels, which can be scraped out during feeding. Alternatively, the feed stall and lying area are combined, with a shared dunging space behind the feed stalls (sometimes called a cubicle system). The second option requires less space, but it is possible that sows may be left in the lying/feed stalls for long periods of time after feeding, so are not ideal.

Electronic sow feeding (ESF)... This is the most technically complex of group-housing systems for sows, as each sow carries an eartag or neck collar containing a transponder with a unique signal. When the sow enters the feed station, her unique ID is detected and feed is dispensed. The day’s ration is dispensed in several drops during one visit and takes 12-15 minutes to eat (longer for gilts, and if meal is being fed). At the end of feeding the feed station opens when the sow chooses to leave, unlocking the back gate (sow-operated system) or the computer unlocks the back gate after a time delay following the last feed drop (computer-operated system). At the end of each 24-hour

feed cycle, an action list is generated by the computer to indicate which sows have not eaten their entire ration. Typically, ESF systems are straw-based and are installed in general purpose buildings with natural ventilation and minimum width of 12-15m. Sow-operated feed stations cater for about 40 sows per station, while computer-operated systems can have a higher number of sows per station (approximately 50). Group size can be flexible, with most systems operating with a large dynamic group using two or three feeders, with regular removal and addition of trained sows (see mixing section). New groups added to the system will generally lie together, and feed later in the cycle. Gilts should be housed separately, as they can find it difficult to compete at the feed station and they take longer to feed.

Assessing welfare

Regular observation of sow behaviour, especially at feeding time, is essential to detect any welfare

problems. A combination of the following factors will indicate a reduction in welfare:

- wide variation in body condition (more sows with lower and higher scores, fewer at the ideal score 3; standard scale 1-5);

- more than 3 aggressive interactions per sow in the hour following feeding;

- the majority of trough-fed sows still active one hour after feed delivery (longer settling times are more usual in floor-fed sows);

- an increase in fresh (pink or bleeding) skin lesions on head, rear or flank to more than 5 per sow;

- any occurrence of vulva biting (sows queuing for an ESF station particularly vulnerable).

The above is only a guide, and the stockperson will quickly pick up on any restlessness or other behaviour changes, resulting in the removal of sow(s) and modifications to the system.

![]()

• Space: provide at least 3m2/sow (for 300kg average group weight) in order to allow functional use of space (areas for resting, feeding, drinking, rooting and social behaviour) and reduce aggression.

• Flooring/bedding: provide solid flooring with quality bedding which is regularly topped up and mucked out. Bedding improves thermal comfort, and helps to reduce hoof lesions, lameness, and skin lesion issues, while improving gut fill and foraging behaviour.

• Fibre and Foraging: provide straw and extra fibre (such as silage) to increase satiety and foraging behaviour and reduce aggression.

• Managing aggression, particularly during mixing: mix sows within 4 days of insemination. Gradually familiarise unfamiliar sows via fence line contact and reduce aggression through ad-lib feeding and provision of ample space for less dominant sows to escape aggressors. Provide physical barriers (such as straw bales) for hiding behind and consider the use of specialised mixing pens.

Click here to read the full report from Compassion in World Farming