Leading on sustainable lysine production

Evonik Animal Nutrition has a long history of working to ensure its products and services are manufactured and supplied as sustainably as possible, benefitting customers and the wider environment.One way Evonik does this is through ‘life cycle assessments’ (LCA). This is a method of evaluating the environmental impacts of a product through its whole life. It considers the extraction and processing of the raw materials, manufacturing practices, distribution, use, recycling and, finally, disposal.

Evonik initially adopted this assessment approach in 2003, when it conducted its first product LCA for MetAMINO®. This was followed by the first assessment of Biolys® in 2004. As its product portfolio, and number of production sites, has increased it has continuously extended its sustainability analysis, built on the expertise of its colleagues.

Flagship sustainable production in Brazil

One of the company’s manufacturing sites is in Castro in Paraná, Brazil. Since 2015, roughly 100 people have worked there on the production of approximately 60 Kilotons a year of lysine HCl equivalent in the formulation of Biolys®.

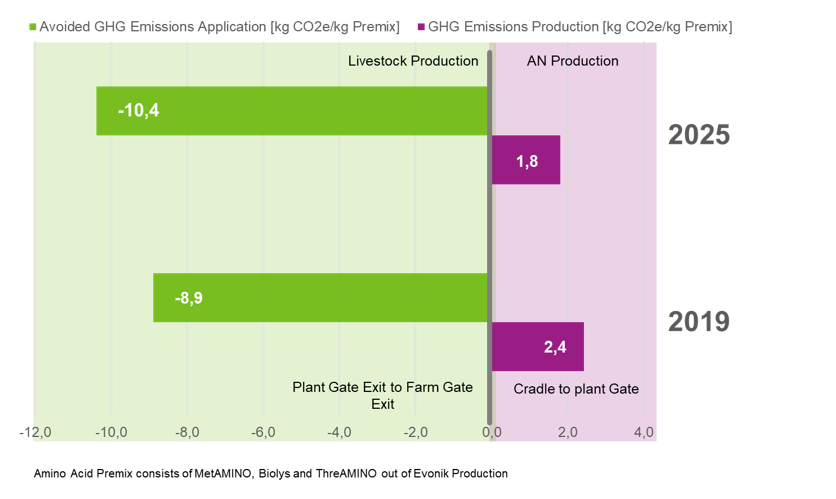

The innovative Biolys® production processes at the site, have now been investigated for the first time to assess its sustainability performance using LCA. The focus was on the carbon footprint, also known as Greenhouse Gas emissions (GHG). Furthermore, Evonik also reviewed the entire life cycle from ‘cradle to grave’ demonstrating the key role of amino acids as an efficient lever to improve sustainability performance of livestock operations [Figure 1].

Evonik Animal Nutrition’s amino acids reduce livestock’s ecological burden. Although production of the amino acid premix emitted 2,4 kg CO2 equivalents per kg premix in 2019, the customer can save 8,9 kg when applying it. By 2025 additional benefits will be achieved by further reducing the crude protein content and further process improvements.

Evonik has continuously optimized environmentally friendly production in Castro and established a veryefficient production process at the site through process improvements, sustainable raw material utilization, new product formulation, and technology upgrades.

Renewable energy use and reduced direct CO2 emissions are key aspects in this approach. This year more than 90 percent of the electrical energy demand at the site will be met by renewable sources, mainly hydropower. This corresponds to a lower global warming potential than the standard Brazilian grid mix. In addition, the steam required during production is completely generated using Eucalyptus wood chips, another renewable source.

The main raw material required in the Biolys (lysine) production process is sugar. At the Castro site dextrose derived from corn is used; importantly, corn captures huge amounts of CO2 while it is growing. The production site is located in a corn growing region and directly next to a corn mill, reducing potential travel emissions alongside the other sustainability benefits accrued in the production process.

With more than three quarters of the total lysine produced in Castro being sold directly in the four states of South Brazil, the Castro facility’s main supply chain is with regional customers, helping to reduce or remove the need for them to import lysine products from other countries and lowering the carbon footprint for everyone involved.

Sustainable product formulation

Ongoing production improvements have allowed Evonik to implement a new product formulation: Biolys 77 with a 10 percent increase in lysine SO4 content compared to the old product formulation (Biolys 70). This improved formulation brings its own sustainability benefits. Whereas the process for the alternative product Lysine HCl requires significant amounts of HCl and produces byproducts, Evonik’s Biolys production process does not separate the biomass (as it brings additional nutritional value to the product) and does not generate any byproducts.

The technology improvements introduced as part of the Biolys 77 implementation have achieved a further reduction in the CO2 emissions at the site; down to 0.23 kg CO2 equivalents per kg of Biolys 77. This low value is influenced by the surrounding agricultural area having been used for more than 20 years as corn fields and to produce agricultural products.

Growing benefits

The benefits of this sustainable approach keep coming. For instance, using Biolys in a lysine-deficient diet significantly increases average daily gain (ADG) and helps to reduce waste emissions through a higher feed conversion rate (FCR) for an improved environmental footprint at Evonik customers’ operations.

The potential environmental benefits of Amino acid use is also now part of FAO’s LEAP[1] Guidelines series (Source FAO LEAP Guidelines). Evonik is looking to see how modern animal nutrition could have a further positive impact for society in the future. For instance, reducing the crude protein content in modern broiler diets in Brazil not only reduces the negative impact of less supplemented diets, but also gives additional contributions to society, including reducing the impacts on land used to produce crops for animal feed and air pollution from the chickens’ waste.[2]

If we are to meet the global food challenge of ensuring our growing population can be fed healthy, nutritious food, it is vital that we take steps to do this in as sustainable a manner as possible. Optimizing the sustainability of production sites and products – while ensuring they maintain their effectiveness – is an important part of that process. The Castro facility shows that it can be done.

| References | ||||

|---|---|---|---|---|

| [1] FAO LEAP: Food and Agriculture Organization of the United Nations: Livestock Environmental Assessment and Performance: http://www.fao.org/partnerships/leap/news-and-events/news/detail/en/c/1206605/ | ||||

| [2] https://home.kpmg/de/en/home/insights/2020/01/building-the-case-for-innovative-animal-feeds.html | ||||