Overcoming bridging issues in bulk feed bins

Bridging issues in bulk feed tanks have been a longtime challenge faced by producers. Both bridging and “rat-holing” inside bulk bins owing to feeds with added fat, extra-fine grinding, and high heat and humidity contribute to inadequate feed flow through delivery systems and frequent out-of-feed events for animals across species. Repeated and unplanned out-of-feed occurrences can negatively affect ADFI and ADG.Historically, the “quick fix” method producers have used to eliminate feed bridging in bulk bins involves blunt-force impact by a hammer or mallet to the bin's bottom cone, collar, or plastic transition. This method, albeit cost effective and relatively simple, can cause severe wear-and-tear to bins and doesn't solve the underlying issue of preventing bridging or rat-holing in the first place.

Many attempts at solving the complications feed bridging causes have been taken on by equipment manufacturers, but no single solution has presented itself as a cure-all for eliminating or significantly reducing the occurrence of bridging issues. Both high-frequency vibration systems and automatic hammering devices help keep feed agitated and flowing, but can seriously affect the integrity of the bin's complete structure, resulting in loosened fasteners and early equipment failure. Additionally, the difficult and time-consuming installation of these devices often make them cost prohibitive for use on large farms.

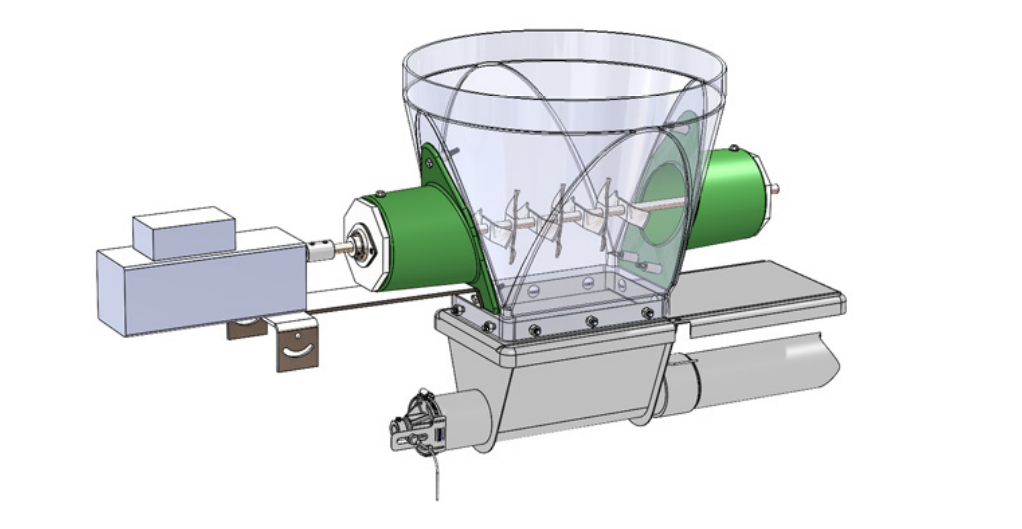

Overcoming the negative effects of high-frequency vibrations or impacting hammers and mallets was the inspiration behind the development of the latest product aimed at improving the reliability of feed flow out of bulk bins. Aptly named Flow Pro, the new bulk feed tank agitator by Osborne features a single, steel agitator inside the bin's plastic transition or upper boot that rotates simultaneously with feed delivery systems. Making about 100 revolutions per minute (RPM), the device automatically provides agitation where it is most needed to prevent bridging and rat-holing issues before they begin. In addition to preventing bridging or rat-holing inside bulk bins, Flow Pro's rotating agitator also breaks up clumped feed before it can enter feed delivery systems and cause plugging of feed lines.

Early testing with Osborne's Flow Pro system has shown promising results at various livestock facilities across the U.S. The system installs on both new or empty bins as well as existing bins with feed. Once feed reaches the device, its gentle rotation helps promote mass-flow and first-in, first-out feed delivery. In addition to eliminating the wear-and-tear bins can experience with vibrating systems, Flow Pro eliminates the need for farm personnel to exit buildings to use a hammer or mallet to get bridged feed flowing, resulting in better biosecurity practices by farm staff.

The Flow Pro bulk feed bin agitator uses an IP66, outdoor-rated, dual-voltage motor and control system to automatically activate alongside feed delivery systems. Sensors indicating the position of slides on unloaders prevent the system from running if slides are closed and bins are not being unloaded. Though the rotation of Flow Pro's feed agitator is gentle enough to not compromise quality or reduce feed to dust, it easily destroys clumped feed before it enters feed lines.

For more information on Osborne's new Flow Pro bulk feed tank agitator, visit osbornelivestockequipment.com/products/flow-pro-bin-agitator. Flow Pro is covered by one or more patents (PAT osborne-ind.com/ip) and is a licensed product of Fat Lump Buster, LLC.