Safeguarding swine health starts at the feed mill and finishes at the feeder

Demonstrating the efficacy of FeedARMOR™ as a new gold standard for feed mitigation

Introduction: Tackling a Hidden Threat in Swine Production

Pathogen transmission through contaminated feed has emerged as a persistent risk to swine health, with viruses like porcine reproductive and respiratory syndrome virus (PRRSV), porcine epidemic diarrhea virus (PEDV), Seneca Valley virus (SVA) and African Swine Fever virus (ASF) capable of surviving feed processing and transport conditions. These viruses not only jeopardize animal welfare but can also have large detrimental impacts on productivity, profitability and the stability of our food supply.

To address this emerging challenge, a new feed tool has been developed: FeedARMOR™, an all-natural feed mitigant designed to reduce the risk of viral contamination and transmission from animal feed to the animals. Backed by scientific evaluation and field data, FeedARMOR represents a proactive solution that supports producers’ biosecurity efforts at an often ignored entry point for disease—feed.

Study Overview: Testing FeedARMOR Against PRRSV, PEDV and SVA

A research trial conducted by Dr. Scott Dee and Pipestone Applied Research evaluated the feed mitigation efficacy of FeedARMOR in a controlled setting. The primary objective: Evaluate the efficacy of various inclusion rates of the feed mitigant FeedARMOR compared to using no mitigant, or the gold standard mitigant in the industry, namely formaldehyde, at reducing the risk of infection following consumption of feed contaminated with PRRSV, PEDV and SVA.

Trial Design Highlights

- Feed Material: Complete swine diet, ground and mixed uniformly.

- Treatments: Feed was treated with either FeedARMOR at various inclusion rates, with the formaldehyde-based mitigant or left untreated as a control.

- Basal diet (as a negative control group)

- 2 lbs/ton inclusion of FeedARMOR

- 4 lbs/ton inclusion of FeedARMOR

- 6 lbs/ton inclusion of FeedARMOR

- 6.5 lbs/ton inclusion of a formaldehyde-based product (as a positive control group)

- Inoculation: Each feed batch received an ice block containing PRRSV, PEDV and SVA on days 0 and 5. The blocks melted, with liquid permeating the feed, forming “a viral hot spot.” Feed was augured into each room which sows consumed via natural feeding behavior.

- Sampling: Feed and oral samples were taken at 0-, 5-, 12- and 27-days post-inoculation.

- Analysis: Feed and oral fluid samples were analyzed via PCR to determine viral RNA presence.

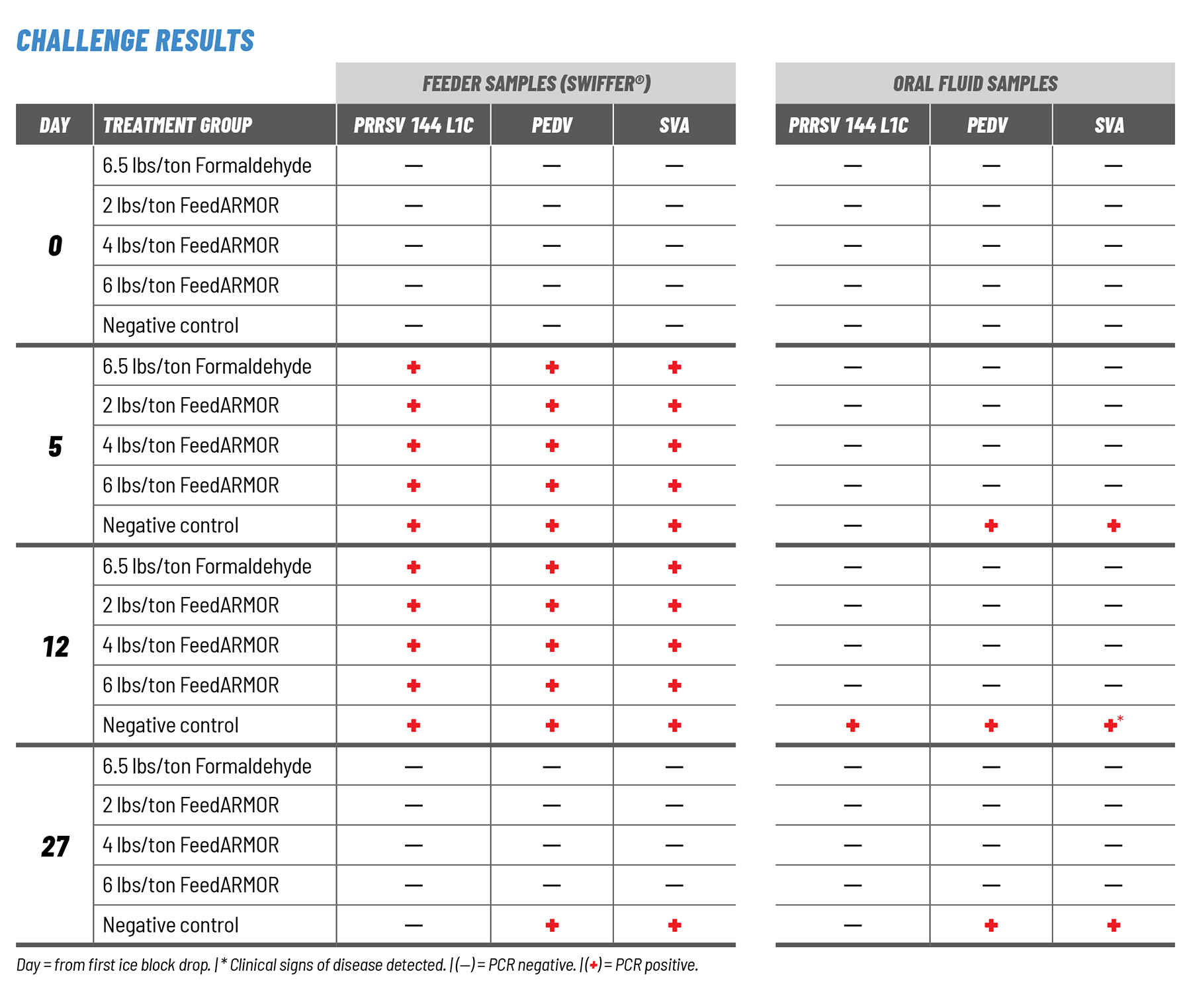

Results: FeedARMOR Provided Immediate Protection

The findings of this trial were clear: FeedARMOR prevented infection for all three viruses tested through its feed mitigation impact, where unmitigated control-fed sows showed clear clinical symptoms and detection of viral RNA in oral fluids.

PRRSV Results

- On Day 5, PRRSV RNA was detected in all feed samples. Oral fluid samples taken on Day 5 were negative for PRRSV in sows consuming feed supplemented with FeedARMOR at all inclusion rates, the formaldehyde-based industry standard treated and the untreated control group sows.

- On Day 12, PRRSV RNA was detected in all feed samples. Oral fluid samples taken on Day 12 were negative for PRRSV in sows consuming feed supplemented with FeedARMOR at all inclusion rates and the sows given the formaldehyde-based supplemented feed. The non-mitigated control group tested positive for PRRSV.

- On Day 27, PRRSV RNA was not detected in feed samples. Oral fluid samples taken on Day 27 were negative for PRRSV in FeedARMOR-treated sows at all inclusion rates, the formaldehyde-based industry standard and the untreated control group sows.

PEDV and SVA Results

- On Day 5, PEDV and SVA RNA were detected in all feed samples. Oral fluid samples taken on Day 5 were negative for PEDV and SVA in sows consuming feed supplemented with FeedARMOR at all inclusion rates and the formaldehyde-based supplemented feed. The non-mitigated control group tested positive for PEDV and SVA.

- On Day 12, PEDV and SVA RNA were detected in all feed samples. Oral fluid samples taken on Day 12 were negative for PEDV and SVA in sows consuming feed supplemented with FeedARMOR at all inclusion rates and for the formaldehyde-based supplemented feed. The non-mitigated control group tested positive for PEDV and SVA.

- On Day 27, PEDV and SVA RNA were detected in only the negative control feed sample. Oral fluid samples taken on Day 27 were negative for PEDV and SVA in sows consuming feed supplemented with FeedARMOR at all inclusion rates and the formaldehyde-based mitigated feed. The untreated control group tested positive for PEDV and SVA.

Why It Matters: Feed Safety is a Key Leg in the Swine Biosecurity Footstool

The feed-to-farm pathway is a major focal point for biosecurity, especially as global trade, supply chain complexity and disease pressures increase. Research by Pipestone Applied Research and others has shown that viruses can survive feed manufacturing, cross borders in ingredient imports and ultimately enter swine populations through contaminated feed.

The goal of feed mitigation technologies like FeedARMOR is to be part of the system that protects your animals.

Application & Dosage

In the study, FeedARMOR was applied at 2 lbs, 4 lbs and 6 lbs per ton of feed and mixed thoroughly prior to viral contamination via the ice cube.

FeedARMOR is a well flowing ingredient that can be incorporated at feed mills through hand-add, micro-system or totes and is compatible with standard feed delivery processes. It does not require any special delivery or handling requirements. It is a ready-to-use solution that requires no additional steps, equipment costs or additional employee safety steps.

Practical Implications: Supporting Swine Producers with Science-Based Tools

Swine producers face increasing pressure to do more with less—protect herd health, ensure productivity and meet evolving market demands. FeedARMOR supports these efforts by addressing a biosecurity risk that has often flown under the radar: Feed as a vector.

- Enhances Feed Safety and Biosecurity: All-natural feed mitigant designed to reduce the risk of disease transmission through contaminated feed, strengthening the overall biosecurity program.

- Proprietary and Patent Pending: Utilizes proprietary composition to aid distribution in feed, and to deliver effective mitigation at very low inclusion such as 2 lbs, or 0.1% inclusion per ton of feed, creating a safer feeding environment.

- Ease of Use: Applied at the feed mill through all modes of implementation to minimize workflow disruption.

The study's real-world relevance—complete feed, common viruses and practical storage conditions—demonstrates that FeedARMOR isn't just a lab solution; it's a farm-ready tool built for the demands of modern production.

Conclusion by Dr. Scott Dee

- The ice block challenge model was effective, successfully transporting all three viruses through the feed into all groups.

- In the absence of a feed mitigant, PRRSV, PEDV and SVA infection occurred, and clinical signs of all three diseases were observed.

- The feed mitigants tested in this trial equally prevented infection and clinical disease across three significant viruses of pigs, despite evidence of viral RNA in feed, which suggests that sterilization of feed may have occurred.

- Under the conditions of this study, FeedARMOR, independent of inclusion rate, effectively mitigated the risk of viral infection via feed.

"In Dee’s mind, the biggest takeaway from this trial is that there is a product out there now that matches formaldehyde’s performance."

“This product also doesn’t have any of the issues with formaldehyde handling. It doesn’t require OSHA and EPA oversight on the mill like formaldehyde either,” Dee adds. “It’s a new kid on the block, and it was pretty impressive in its first time around.”1

FeedARMOR provides broad-spectrum efficacy against pathogens. Research has shown effectiveness in mitigating viruses, contributing to improved feed hygiene and animal health. The product’s performance in this study affirms its role as a valuable biosecurity tool—one that producers can trust to help reduce viral risk at a critical control point.

As the livestock industry continues to elevate its standards for health, safety and sustainability, innovations like FeedARMOR will be essential in safeguarding the health of animals and the integrity of the food chain.

To learn more about FeedARMOR and access the full research findings, visit www.FeedARMOR.com.