Retrofitting for Group Housing of Sows

This paper, presented at the 2014 London Swine Conference by Sylven Blouin of Agri-Marché in St-Isidore in the Province of Quebec, describes the conversion of two farrow-to-finish units to group housing.

The new code of practice will be a challenge for most of the independent producers and smaller organisations of the province of Quebec who represent a large part of the pig production.

Retrofitting for the new demands for group housing means new costs, new ways of raising animals and for now, no more expected revenues.

What is new can seem frightening at first. By having more information from other producers and visiting, when possible, other farms converted to large groups, the experience is actually quite rewarding.

This paper describes the conversion of two farrow-to-finish units in 2013, owned by Agri-Marché. The author presents the reasons why different choices of technologies have been made for those projects; the challenges people have faced and costs.

The CDPQ (Centre de Développement du Porc du Québec) has produced an evaluation of the economic impacts of the new Code on costs of construction and retrofits of the Quebec pig barns; some details of this report will be presented.

Pig Production in Quebec: a Brief Overview

In the report (Pouliot et al., 2012), the authors have tried to roughly estimate the number and age of pig farms in the province that will eventually have to comply with the new code requirements (Table 1).

| Table 1. Estimate of average age of farrowing barns and finishing in the province | ||||||

| 16 years and less | 17 to 21 years | 22 to 26 years | 27 to 31 years | More than 31 years | ||

|---|---|---|---|---|---|---|

| Proportion of barns (%) | 48.1 | 18.0 | 8.3 | 4.5 | 21.1 | |

| Number of barns1 | 767 | 287 | 132 | 72 | 337 | (1,595) |

| Number of finishing barns2 | 1,472 | 551 | 254 | 138 | 646 | |

| 1 BPR Groupe-conseil et Groupe Agéco (2001) 2 FPPQ, 2011 |

||||||

The number of farms that are already compliant with the new rules of welfare would be about ± 35 currently in Quebec representing 25,000 sows (CDPQ 2013). The total sow herd in 2012 (Statistics Canada) was approximately 317,000 sows; the average farrowing herd was at that time around 200 sows per farm.

According to an internal survey (not scientific), a good proportion of Quebec independent producers do not currently intend to invest in their farms to comply with the rules of 2024. The amount to invest, no expected compensation for now and no family takeover make them think they will sell or just close their farm. On the other hand, people so far are more or less well informed about the changes it will involve.

Those who have made the changes are generally quite satisfied and say simply that it is a different way of raising sows that brings a part of good and bad sides. It is to think that after the shock of the adoption of the new code, producers will receive more information and options for changes to their farm and they might change opinion.

There will certainly be some coming changes in the industry but with the structure of production in Quebec, it is expected that the inventory of sows will not change a lot, at least if we only consider the effect of the new code.

The Projects

Agri-Marché, a company that operates primarily in the manufacture of feed for the animals at the farm has a little over 15,000 sows divided into 19 sites in Quebec and one in Ontario. The age of these sites varies from five to 37 years. The business model brings the company to offer a multitude of services to independents dairy, poultry and pork producers.

The swine division offers, beside feed, replacement gilts (pregnant or not), boars, semen and advice related to all aspects of production. With the arrival of the new Code, the management team received the mandate to acquire the necessary expertise in large group housing to better advise customers in their future choices.

In early 2012, people were commissioned to investigate the available technologies, visit sites already in production both in America and Europe, develop a network of contacts and create a guide for conversion to large groups for our own barns and the customers.

The ultimate goal is to convert all sow barns connected directly or indirectly to the network by 2022, the date targeted by our customer for commercial pigs.

The network of farms belonging to the company consists mainly of farrowing units, selling weaners except for six sites in 2012 that include nurseries and fattening. Most of these six sites are quite old and with improved sow prolificacy, the capacity of nursery and finishing is not sufficient any more. We have to transfer some piglets elsewhere and that doesn't suit with the philosophy of production. The opportunity is thus ideal to convert these units.

For the first three, the decision was made to transform them in grower farms only, for the other ones, it was decided to retrofit to farrowing units.

In 2013, the retrofit of the first two sites to large group housing started and, to meet the original mandate of the project, it was decided to use the two most opposite technologies available at this time: floor feeding for the first project and the ESF for the second.

First Project Description

The first farm is a multiplication unit of 250 sows that was raising only the gilts, barrows being sold to a small finishing barn located 30 kilometers from the farm. This farm built in the 70s is no longer functional for the reasons mentioned above and it is already decided to no longer use it for production of gilts despite its excellent location and its very good health status. It was decided to convert the unit into a farrowing unit of 625 sows weaning every 28 days for production of 1200 to 1,300 pigs per band, which is slightly more than the minimum amount of piglets sought from each of our weaner suppliers.

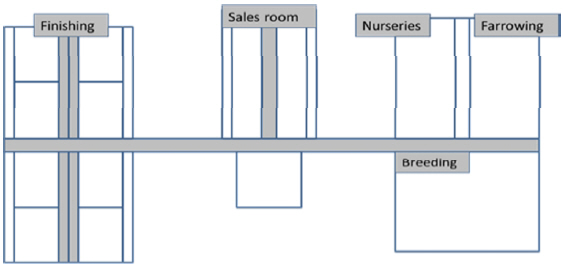

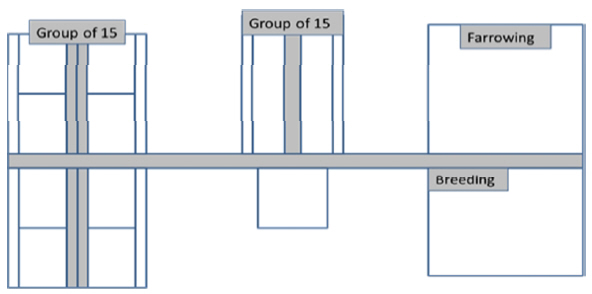

The renovation of the fattening and selection was fairly simple because it was converted to floor feeding (Figures 1 and 2). Former grower pens are a total length of 18.5 feet, a width of 8.0 feet with a slatted part on the back of 4.0 feet. Pens in the selection room have the same dimensions.

To create groups of 15 sows, the old feeder and the gate between two pens was removed. With two pens, we then create a single one with 19.8 square feet per sow.

The breeding room did not have to be modified, just a few repairs. Its capacity is 196 sows and gilts; we can keep them in that room up to the second pregnancy test for most of the females – usually they keep gilts in pens after breeding – before moving them in large groups.

The old nursery was more complicated to modify. Concrete had to be removed, building a new manure pit which represent a large part of the total expense. Used farrowing crates (washed and disinfected) were installed.

Especially with the PED concern now, Sylven Blouin said this is not something they would do again without a lot of investigation. The total cost to raise the sow herd from 250 to 625 sows has been around $400,000, so $640 per head.

Second Project Description

The second barn looks like the first one except for the year of construction (1999).

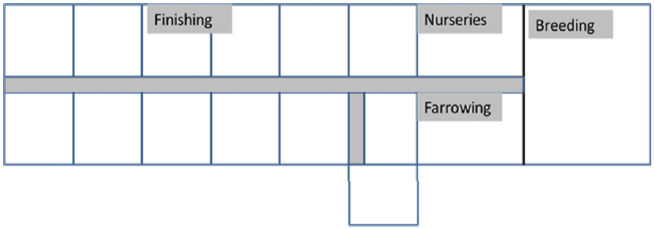

An advantage of this site is that weaning takes place in farrowing crates. The total building footprint and the availability of at least 131 farrowing crates brings the ability to transform this farm into an 850 sows unit without having to invest heavily in the maternity section (Figures 3 and 4). Only the addition of 20 additional crates in the selection room had to be done. Using batch farrowing every 28 days, it will provide around 1,500 to 1,600 piglets per weaning.

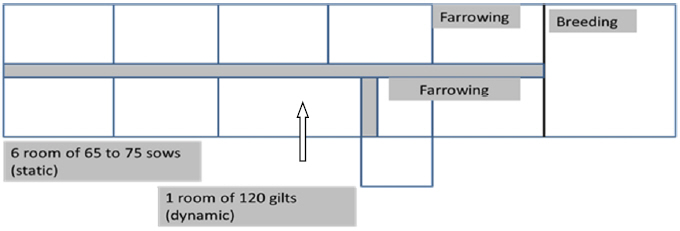

The technology used for this project is ESF. To create large pens from 120 to 150 sows in the fattening rooms of the site, two walls (which separate three rooms) are removed for a larger room of 105 feet long by 31 feet wide (area about 24 square feet per animal), this area is then separated in the middle by an open gate.

An ESF is then installed in each half-room (6) created. As originally this barn had 11 rooms, nine of them have served to form static groups for sows, the remaining two forming a large room of 70 feet long by 31 wide to operate a maximum of 110 gilts, a dynamic group for them (about 20 square feet per animal).

It was decided from the beginning not to change floor design to reduce renovation costs - approximately $150,000 to $175,000 savings. The floor has half-solid area in the center and half slatted.

The group knew that it would be a challenge so several designs have been used to create clean areas for each sow or gilt. The normal design with the ESF used is a pen of about 22 to 23 feet wide. As theye had 31 feet, theye had to adapt by using a few tricks to get the desired rest areas.

After several tries, a plastic panel was installed on the solid areas (Figure 5), which allows us to keep our animals in a very satisfactory state of cleanliness despite only 45 per cent of the floor is slatted.

Again, the breeding section of the farm has not had to undergo changes. With a capacity of 260 sows, it can keep the animals until the second pregnancy test for the majority of subjects but we still expect to have to test sows or gilts in large groups.

Maternity section that already has 131 crates has requested the purchase of 65 additional troughs and side sections. Twenty additional used farrowing crates were added in the old selection room where we have had to remove slatted floors to install the crates after slight modifications. The total cost to go from 250 to 850 sows amounted to $323,000, or $380.00 per sow.

Some Information Published by the CDPQ

As seen with the two projects, the total cost of a modification of the building is greatly influenced by the characteristics of the farm of origin. The starting point in both cases was that we did not want to leave the existing walls because it is very difficult to do in Quebec with the current rules without counting the costs it generates. It is quite surprising that between these two projects presented, it is the barn with the most sophisticated equipment that has a lower cost of renovation.

CDPQ in its economic assessment examined the potential costs of several assumptions processing in large groups. There are several scenarios for maternity; the first one is a 2,400-sow unit (new construction), the second, a retrofit of a 600-sow farm to group housing and another scenario with a 250 sows farrow to finish. The scenarios are very different from each other but the study provides a good idea of the differences that may exist between different options and once again, the original features of the building vary the renovation costs. Table 2 presents one of the scenarios of the report.

| Table 2. Comparison cost: retrofitting of a 250-sow farrow-to-finish by using actual footprint (31,374 square feet) |

|||

| ESF | Short stalls | Free stalls | |

|---|---|---|---|

| Number of productive sows | 750 | 700 | 650 |

| $ per productive sow | 932 | 910 | 1,277 |

| $ per square foot | 22.28 | 20.31 | 26.47 |

| CDPQ 2012 | |||

Conclusion

The ideal system does not exist; people build new barns for many years and each time, improvements are made even if they are minor. In a case of renovation to house sows in large groups, it is often a matter of compromise if you want to adapt the building to the new rules.

The first point to respect appears to be the area to be given to animals according to the standards of the Code. Then, depending on the technology chosen, we must decide whether the groups will be operated in static or dynamic management, the number of subjects per group, the need for rest areas etc.

Both systems presented above have their share of benefits, the first one for its simplicity of operation for example and the feeding accuracy of the ESF system on the other end. But, they also have some bad sides (training gilts to use ESF, for example).

Errors were made in the two projects, but we must learn to live with them. A solid floor in traffic areas with the ESF system would have been better but it was worth it to try not to touch the existing floors and modify the design of pens to find an acceptable solution because the amount saved was important.

Literature Cited

Centre de développement du porc du Québec inc. (CDPQ)

Pouliot, F., S. Turcotte., M-P. Lachance, J-F. Forest, B. Turgeon. 2012. Évaluation de l’impact économique des exigences de bien-être animal sur les coûts de construction et de rénovation des bâtiments ainsi que sur la rentabilité des élevages porcins du Québec. CDPQ.

Reference

Blouin S. 2014. Retrofitting for group housing. Proceedings of the London Swine Conference. London, Ontario, Canada. 26 to 27 March 2014. p66-71.

Further Reading

You can view other papers presented at the 2014 London Swine Conference by clicking here.

November 2014