ARM & HAMMER’S THE SCIENCEHEARTED CENTER is uniquely state-of-the-art

Advanced tech is driving research and industry solutionsPart of Series:

Next Article in Series >

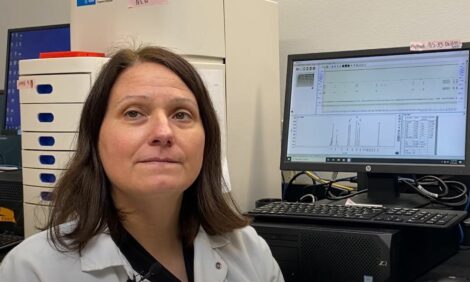

Dr. Xandra Smith, Director of Innovation and Product Development for Arm & Hammer Animal and Food Production, offered a tour of Arm & Hammer’s unique Research and Development facility in Waukesha, Wisconsin, USA to The Poultry Site’s Sarah Mikesell.

“At the SCIENCEHEARTED CENTER, we develop targeted microbial solutions to improve animal performance,” said Smith. “We also work with animal-based protein processing to enhance food safety.”

One of the ways ARM & HAMMER helps improve animal performance is by looking at customers’ facilities to see which pathogens or other stressors are on their farms. That information and data is used to develop new solutions or a solution that is specific to a customer’s needs.

“We’re continually doing research to better understand what issues our customers are facing, so we can develop new products and technologies for them to overcome some issues that they are either facing right now or will be in the future,” she said.

What’s unique about The SCIENCEHEARTED CENTER?

“What's really unique is the people we have here -at the lab we have extremely passionate, educated scientists,” she said. “We also have a lot of different scientific disciplines that we work in.”

Smith shared just a few examples:

- Bacterial genetics. ARM & HAMMER is sequencing the bacterial genomes of both pathogens and some beneficial microbes to develop an in depth understanding of them.

- Microbiota. Studies are conducted looking at the bacteria, archaea and fungi present in an animal’s gastrointestinal tract. The team is learning how the microbiota changes as the animals age as well as looking at different performance characteristics.

- Immunology. A team is studying poultry, pigs and ruminants to better understand how ARM & HAMMER’s products affect the immune system while learning what happens to the immune system as animals grow and develop with the goal of improving lifetime performance.

“We are continually developing new products,” Smith notes. “We receive a lot of environmental samples that are screened for either spore-forming bacteria or lactic acid bacteria that we can use to test and develop new products. we've been increasing our automated liquid handling capacity using robots so we can take in more samples from our customers, both in the US and globally. We continue to develop our robotic systems so that we can handle more samples coming in to help our customers.”

Smith said her team is continually reviewing journals and literature to monitor advancements across species and around the world.

“We do a lot of collaboration with academic universities and others to ensure we stay on the cutting edge and know what the new technologies are that can be used to help us develop new products,” she said.