Better manage your sow herd with uniform body-condition technique

After noticing an alarming difference in sow body conditions in several herds, Cary Sexton, DVM, Four Star Veterinary Service (FSVS), became concerned.

“I saw people that were highly subjective in their ideal animal body conditions,” he said. “On farms with multiple employees who evaluate sows, I saw a lot of group-to-group variability among sow groups in crated gestation. Pen gestation was even more variable.”

The variability among sows was especially concerning because feed budgets are based on sow condition, explained Sexton who is with the FSVS Kinston, North Carolina office. If the herd isn’t uniform, then some sows eat too much feed, and others don’t get enough.

The solution

Sexton looked at different ways to objectively determine sow body condition. Most were eliminated including ultrasound and fat-depth measurements, which requires a high level of technical skill.

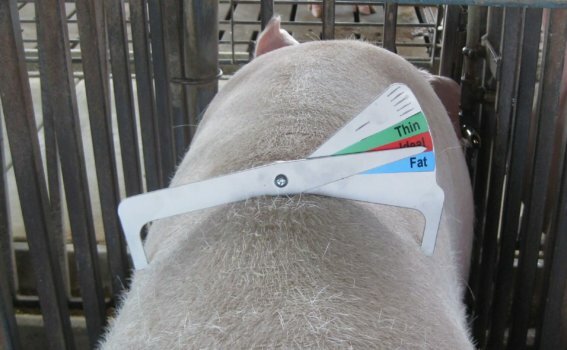

He decided to focus on a sow caliper designed by Mark Knauer, PhD, swine specialist at North Carolina State University Extension. Knauer agreed to meet with Sexton and some pork producers to discuss the caliper.

Knauer designed the sow caliper to standardize sow body condition instead of relying on visual scores, which can lead to expensive herd problems. Underfed sows more frequently experience impaired reproduction and well-being issues. Overfeeding sows leads to higher feed costs, more farrowing problems and higher pre-weaning mortality.

Implementing sow caliper

The sow caliper is a sturdy metal device that’s designed for easy use on sows. After Knauer demonstrated the caliper, Sexton said producers were supportive about trying it in their herds. Employees were less supportive, with concern about how long it would take to measure sows with the caliper.

“But once they used it, the employees felt they were doing a better job determining body condition than previously,” Sexton said. “And most employees can do it in about the same time as they previously were taking in performing visual scoring.”

The caliper must be used properly to accurately determine body condition. Sexton said the caliper must be placed at the last rib and with the pivot point on the spine for proper calibration.

He recommends checking sows with the caliper at breeding, pregnancy check at 50 to 60 days, and at 90 days. Gilts can be started at pregnancy check or after to prevent interfering with conception. It can also be used in a gestation pen system if the animals are housed in crates until pregnancy check or beyond.

“The first few weeks of pregnancy are the cheapest time to recover condition lost during lactation as the sows have less nutritional demand from the next litter,” Sexton said. “The condition can also be carried over into the gestation pens in assigning them and being able to more closely manage the amount offered each animal.”

$250,000 feed savings

Some of Sexton’s clients have used the sow caliper for several years. The biggest change for them was sow feed management.

“We saw huge feed savings for some companies, and one system saved $250,000 a year,” he said. “For a few systems where the sows tended to be thinner, there was a feed increase but with better management and feed utilization.”

Sexton said his biggest surprise was seeing how the small differences between body conditions can cause big variabilities in the animal. For example, he’s noticed sows in good body condition with adequate nutrition will handle disease challenges better.

Another benefit of well-conditioned sows is more piglets born live at the second and third farrowings, he said. The sows also continue to hold the higher numbers in subsequent farrowings.

Employees regularly using the sow caliper also observe sows more frequently. Health issues like lameness can be caught early and addressed before growing into major health problems, Sexton added.

For more information on the sow caliper, contact Mark Knauer.