Study: What do we know about biosecurity measures for wean-to-finish sites?

Study assessed current status of bioexclusion practices across the US swine industry

Editor's note: The following was presented at theiowa State University McKean Swine Disease Conference.

Introduction

Currently, most biosecurity investments in the swine industry are primarily directed toward protecting sow farm, with a lack of information on which biosecurity measures are commonly implemented in the wean-to-market pig population. This knowledge gap is concerning considering the wean-to-market pig population's role in maintaining and spreading pathogens within the industry, causing significant economic losses.

Studies have estimated that more than half of the groups of growing pigs that are negative at placement for porcine reproductive and respiratory disease virus (PRRSV) become positive by finishing, which leads to economic losses of approximately $2.29 per pig. Also, if pigs are infected with both PRRSV and porcine enteric coronavirus (PEDV) during the growing phase, the economic losses reached $7.08 per pig compared to pigs that remained negative for both diseases during the whole phase. Therefore, the objective of this study was to assess the current status of bioexclusion practices adopted in wean-to-market sites across the US swine industry.

Materials and Methods

The data for this study was collected using a questionnaire and answered by the herd veterinarian(s). The dataset included information from 18 swine production systems. The survey was divided into seven categories related to wean-to-market biosecurity aspects: system/region characteristic of growing sites, site summary, vehicles/deliveries, people movement, manure removal, water entry, and live haul sanitation.

The category vehicles/deliveries had subcategories that included all vehicle movement into the farm, such as mortality disposals, feed trucks, and garbage trucks. The people movement category also had subdivisions separating farm employees, visitors, and hired crews. To estimate the industry overall and within the adoption of each bioexclusion measure, we used the inverted sample weights method.

Results

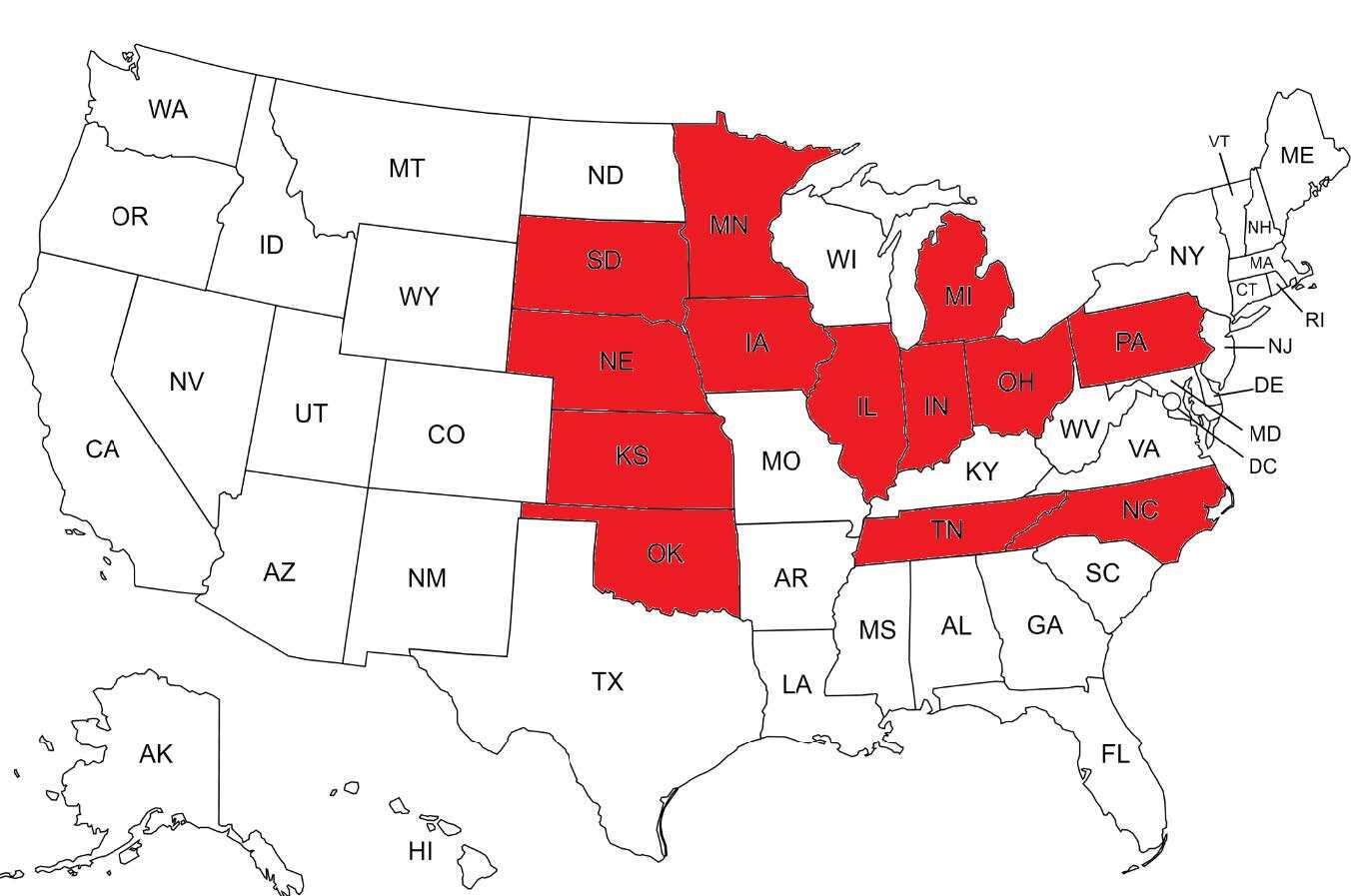

The preliminary results described in this abstract include a population of 15,685,168 growing pigs in 3,670 sites across 13 states (IA, IL, IN, KS, MI, MN, NC, NE, OH, OK, PA, SD, TN). Those sites were classified as nursery (10.61%), finishing (52.1%), or wean-to-finish (36.9%).

Among the production systems, 93.4% use all-in-all-out pig flow procedures while 6.6% utilize continuous flow. Even though all the systems have a set of unique system-specific biosecurity measures, only 83.3% have comprehensive communication procedures to inform the employees about the biosecurity measures to implement when outbreaks occur. In addition, only 77.7% annually audit their sites for biosecurity measure compliance and 16.6% do not conduct any audits.

Regarding the vehicle/deliveries category, for animal disposal, 33.8% of mortality disposal locations are on-site, 65.1% are off-site, and those off-site disposals are mostly (68.7%) directed to shared rendering . The average number of employees entering a site per day was two, with a range of one to four employees. The percentage of employees entering more than one site per day were 28.67% (Nursery), 36.44% (Finishing), and 27% (Wean-to-Finish). While the majority of sites (65.89%) have showers, less than half require showering in or showing out (41.28% and 43.39%, respectively).

The average number of manure removals is 1.52 per year; 56.1% of removals are done by a third party that removes manure for other producers or production systems. Most sites (88.6%) have wells for the water source and 63.5% of the drinking water is not treated.

Lastly, while 100% of the trucks that haul wean pigs are washed and disinfected between every load, for feeder pig trucks, 67.94% are washed, and 70.72% are disinfected between every load; for market pigs, 85.28% are washed, and 67.22% are disinfected between every load.

Conclusion

For a pathogen introduction to occur, biosecurity hazards must lead to a series of bioexclusion failures. To be able to identify those possible failures, first, it is essential to understand the hazard and what control measures must be in place to mitigate the hazard. This study enables us to understand which biosecurity measures are utilized for wean-to-finish sites industry-wide. The next step in this study is to develop a risk assessment tool for PRRSV and porcine epidemic diarrhea virus to identify the gaps in biosecurity measures.