Managing piglet microbial environment with positive biofilms

Scientific trials show positive effects of biofilms in piglet and sow buildingsIn pig farming, a high level of hygiene and biosecurity can significantly improve production costs. The difference in profitability between swine farms with high biosecurity levels and those with lower levels has been estimated at around 200€/sow/year (Corrégé et al., 2012). A new tool in the farm biosecurity management toolbox is the application of a positive biofilm following cleaning and disinfection. Trials and scientific studies in piglet and sow buildings show positive outcomes.

Microbes are everywhere

In farm buildings, all surfaces — floors, walls, ceilings, and equipment — are colonized by microorganisms mainly in the form of biofilms. These biofilms can be harmless, positive, or even negative for the animals if they contain pathogens.

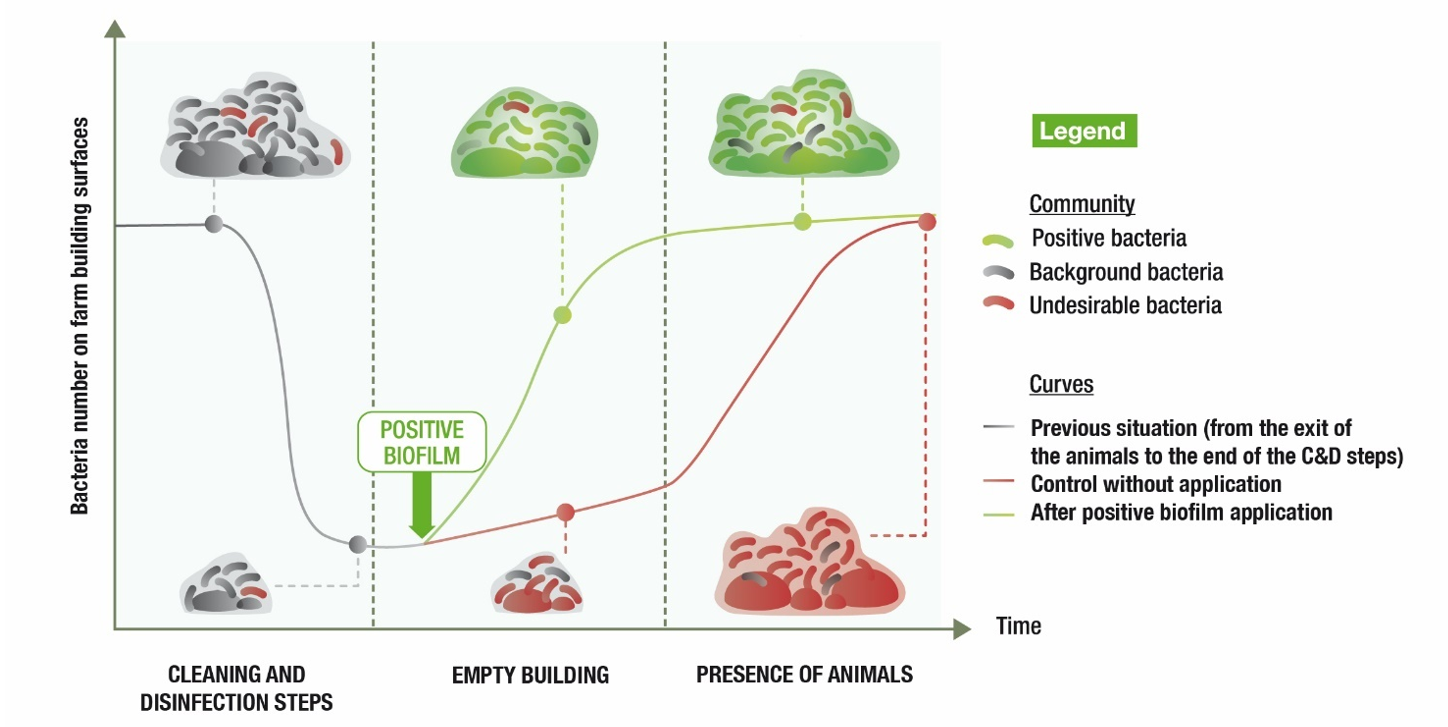

Before a new batch of animals enters the building, cleaning, and disinfection are necessary. However, the surfaces do not remain sterile. Microorganisms carried over from the animal environment (air, dust, litter, housing equipment, etc.), and from the new animals themselves, quickly start recolonizing the surfaces, forming biofilms. These microorganisms can be undesirable bacteria or potential pathogens.

What are biofilms?

Did you know that 90% of the bacteria biomass on Earth is organized as biofilm? A biofilm is defined as “a community of microorganisms attached to a surface” (adapted from Costerton et al., 1999).

They secrete a protective extracellular matrix, which can represent 85% of the biofilm biomass. Biofilms can represent very complex ecosystems developing cell-to-cell communication systems (quorum sensing). A biofilm can be formed either by beneficial (i.e. positive biofilms) or by undesirable (i.e. negative biofilms) bacteria.

A major concern is that some pathogenic bacteria in a biofilm form can be 10 to 1,000 times more resistant to antimicrobials or disinfectants compared to isolated bacteria (Briandet et al., 2012, Cabeca et al., 2012).

In animal production, any farm building or feeding equipment surface hosts biofilms that can be a potential threat to animal health if not well managed.

The positive biofilm concept

The idea is to apply beneficial bacteria along the building surfaces and equipment right after cleaning and disinfection. Those beneficial bacteria can develop into a positive bacteria biofilm inside the building, leaving less room for the development of negative biofilms (Figure 1). This is the positive biofilm concept.

Thus, a new approach to biosecurity management is possible, which includes three main steps:

- Cleaning

- Disinfection

- Application of selected bacteria that will form a positive biofilm.

Farm trials and in vitro studies have shown the potential of this new concept as part of the farm biosecurity management toolbox.

To develop a positive biofilm solution (LALFILM PRO), microbiology experts at Lallemand Animal Nutrition have selected specific bacteria strains for their ability to form a biofilm and rapidly occupy the farm surfaces.

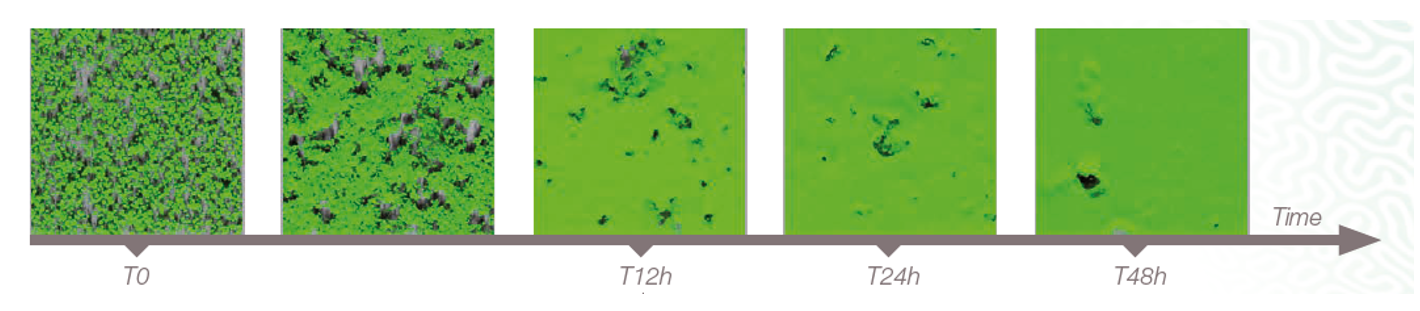

The positive biofilm formed by the selected bacteria rapidly takes up the space on farm surfaces. In vitro testing shows 90% surface coverage after 12 hours (Figure 2), leaving less room for undesired bacteria.

The selected bacteria were formulated into a specific adhesive blend that can be sprayed on both vertical and horizontal surfaces.

Proof of concept

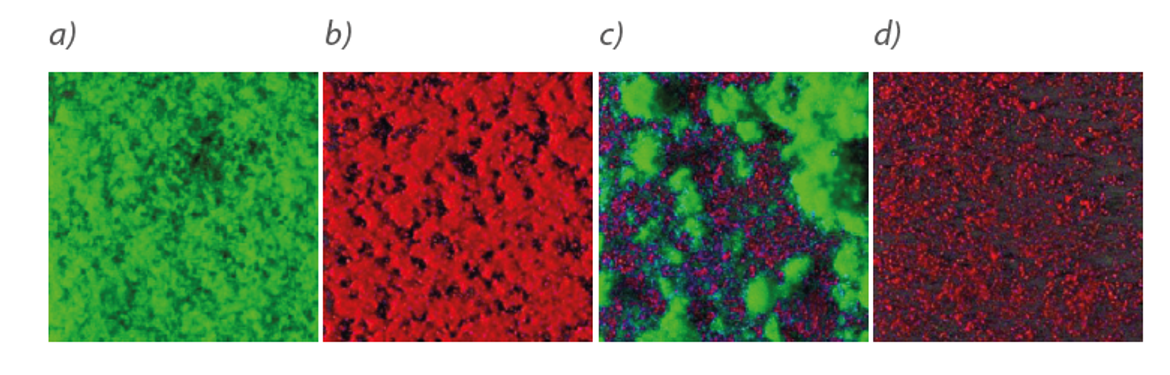

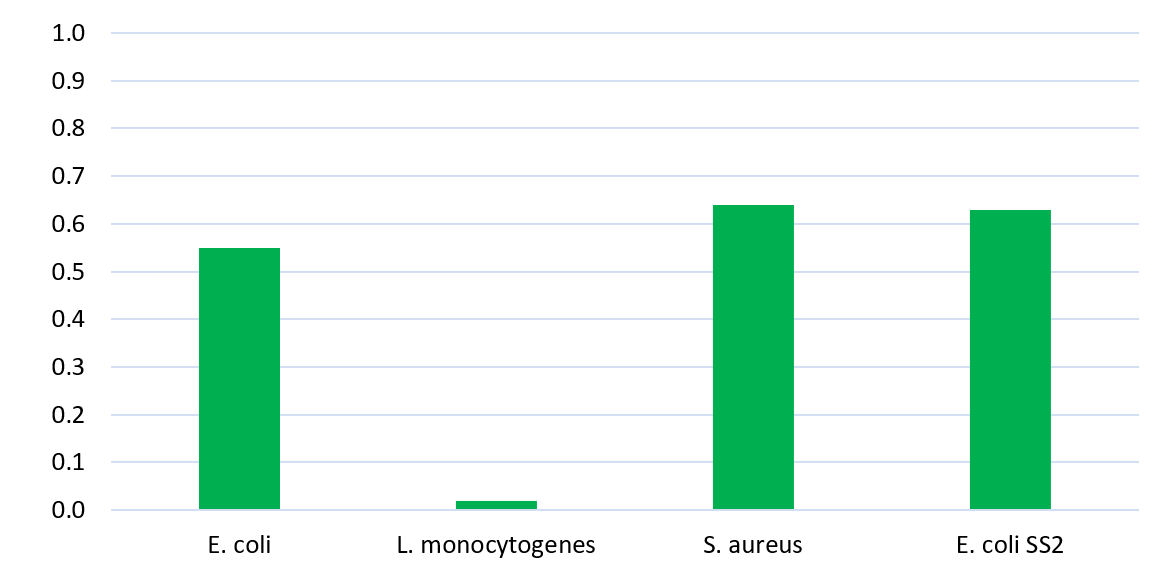

An external in vitro study conducted by INRA Micalis (Paris) allowed scientists to visualize the interaction between LALFILM PRO positive biofilm and different microorganisms (Staphylococcus aureus HG003, Listeria monocytogenes LO28, Escherichia coli SS2 and Escherichia coli 977 in this case). Coupons were inoculated either with LALFILM PRO or the tested microorganism alone (control). 24 hours later, the tested microorganisms were added on top of the LALFILM PRO biofilm. Figure 3 shows one example of the positive and negative biofilms visualization.

To quantify these results, the researchers analyzed the microscopic images to calculate relative biofilm volumes (Figure 4). It shows that for the four microorganisms tested, LALFILM PRO helps avoid colonization by undesirable microorganisms.

In the context of pig farming, the positive biofilm approach is of particular interest in the maternity and post-weaning phases. Several on-farm trials indicate benefits in both environments.

Benefits in piglets

A trial was carried out in piglets for five months with three consecutive batches of 2,318 piglets on a commercial farm. The positive biofilm was applied in two rooms vs. two control rooms. Microbial sampling was performed during the first batch within the animals’ surroundings (specific petri dishes left on slates).

- The application of the positive biofilm generated the formation of a positive microbial environment. Consequently, the development of undesirable bacteria in the animal environment (Streptococci, coliforms) was lower.

- As a consequence, the overall piglet mortality rate (3 batches) was reduced from 1.46% to 0.43%.

Such a trial corroborates the fact that the application of a positive biofilm solution to complement cleaning and disinfection procedures helps maintain a safe microbial environment before the entry of the animals and, thus, contributes to preserving the good hygiene conditions of the building.

Application in farrowing

In farrowing rooms, a trial conducted in Italy on a commercial farm shows similar benefits. LALFILM PRO was applied on the walls and floors of the farrowing room 4 hours after disinfection and 3 days before the sows’ entrance.

Microbial sampling in the environment was carried out with a swab on slatted floors at plastic walls at different time points. Again, the positive biofilm solution helped to maintain a positive microbial balance in the building:

- The development of undesired microorganisms was lower in the control room than in the positive biofilm room:

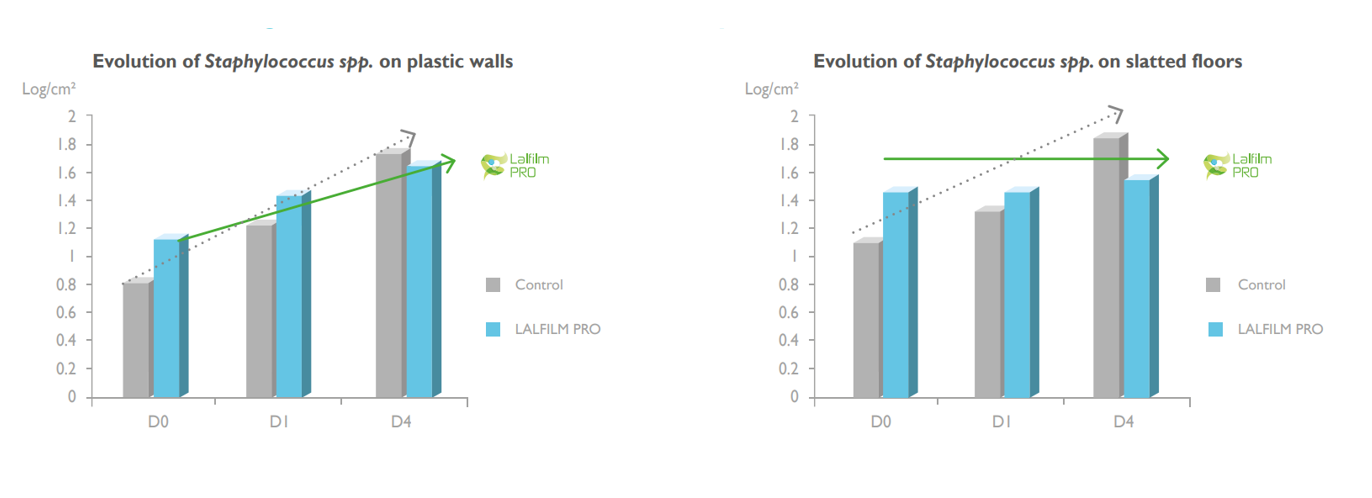

- Staphylococcus spp. Staphylococcus spp. were present in both LALFILM PRO and control rooms and on both surfaces. In the control room, bacteria count showed an increase over time of Staphylococcus spp. on the plastic walls and slatted floors. With the use of LALFILM PRO positive biofilm, the speed of growth is reduced on plastic walls from 1.1 to 1.6 log/cm² and almost stabilized on slatted floors from 2.9 to 3.0 log/cm². At D4, Staphylococcus spp. concentration is lower in the treated room on both surfaces. (Figure 5).

-

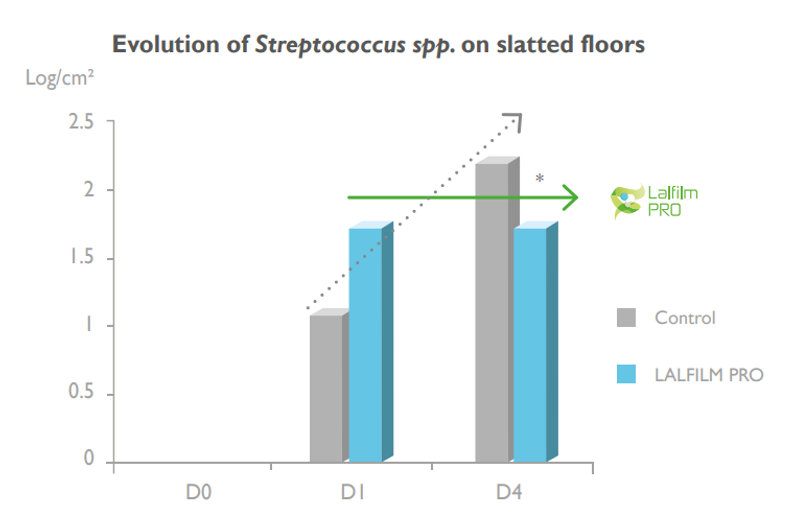

Streptococcus spp. was also observed on slatted floor surfaces. Again, the positive biofilm implementation helped limit their growth. In the control room, Streptococcus

spp. concentration increased from 1.1 log/cm² at D1 to 2.2 log/cm² at D4 whereas it stopped at 1.7 log/cm² for the positive biofilm room at D4 showing a significant reduction compared to the control room. (Figure 6).

Figure 6: Evolution of Streptococcus spp. contamination on slatted floors of farrowing room with and without positive biofilm application in LOG CFU/cm2 (*p = 0.029). Day 0 corresponds to the entry of the sows. (Lallemand Animal Nutrition, internal data, Commercial farm, Italy, 2017).

Conclusion

Pig farm biosecurity measures — including cleaning, disinfection, and application of sanitary breaks — impact the level of infection pressure before new animals enter the barn. Integrating a positive biofilm approach is shown to be an effective tool to complement these measures. It helps improve the microbial environment after the disinfection step and during the batch.

In today’s health context, ensuring a safe microbial environment during the whole production cycle is a must, and new approaches to biosecurity that combine disinfection and a virtuous microbial ecosystem management approach are very promising.

Do you want to know more about positive biofilms and their importance in farm building?

To learn more about LALFILM PRO, consult our website: https://lallemandanimalnutrition.com/en/europe/products/lalfilm-pro

References available on request